-

EXTRUSION 320

Extrusion LineINDUSTRIAL VACUUM CLEANERS FOR METAL & PVC CHIPS

The 320 vacuum cleaners of the Extrusion line are designed specifically for industrial purposes, this model is equipped with powerful motors and an advanced filtering system. Its vacuum characteristics and air flow rate make it ideal for the suction of chips or dust. The use of a cyclonic pre-filter captures more than 90% of the suctioned material before it reaches the main filter, thus preventing it from clogging and considerably extending its life. -

EXTRUSION 38

Extrusion LineINDUSTRIAL VACUUM CLEANERS FOR METAL & PVC CHIPS

The 38 vacuum cleaners of the Extrusion line are the most compact of the iVision range. They are used together with small single -head saws with low production of chips and dust, as they are ideal for the collection of light materials such as PVC, aluminum and other light alloys. The compact dimensions of the Extrusion 38 allow the operator to move with agility in confined spaces while maintaining an excellent quality standard in terms of suction and filtration efficiency efficiency. Thanks to the three-phase motors these vacuums cleaners can safely work continuously with minimal maintenance. -

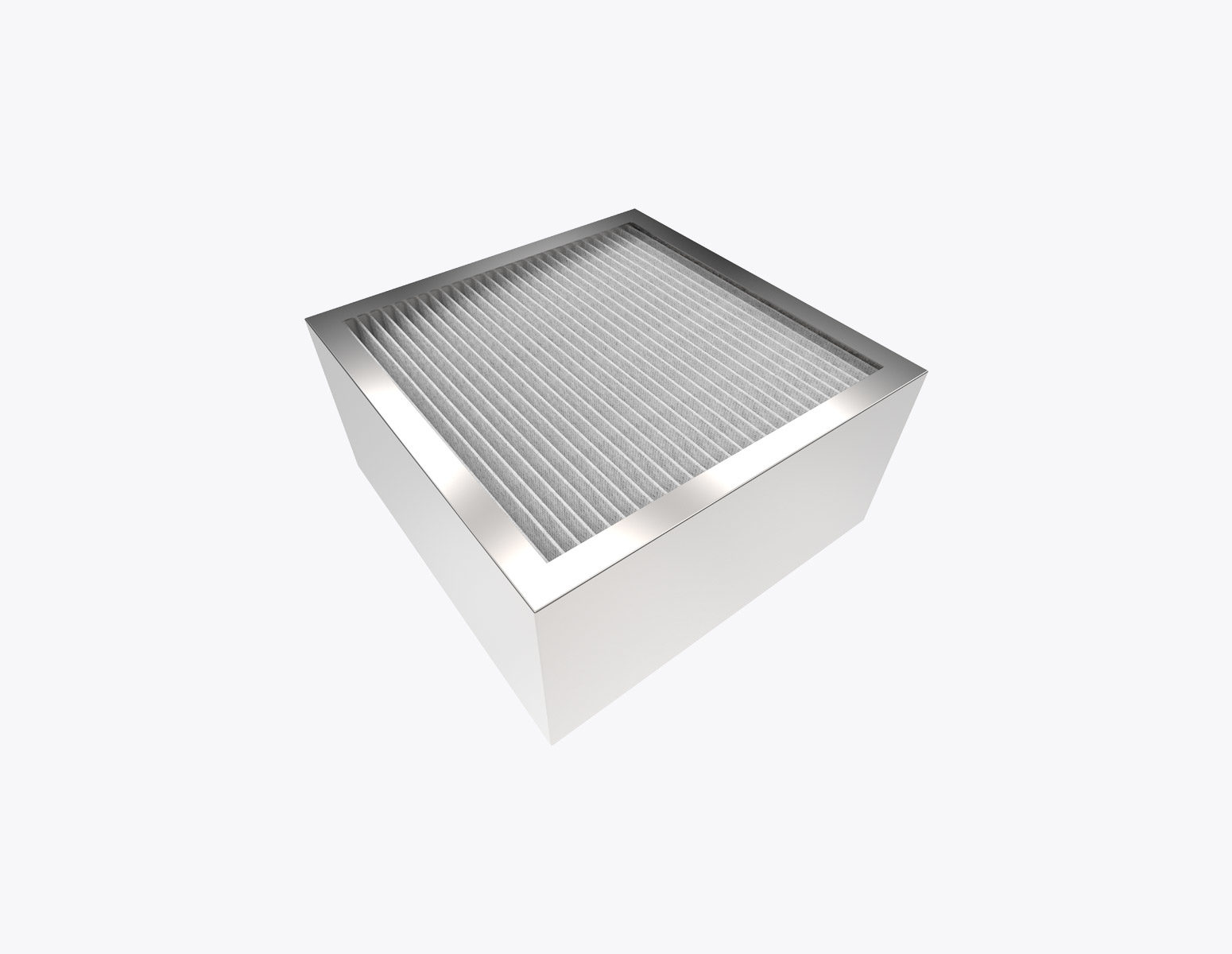

FILTER FOR VACUUM CLEANER

AccessoriesIVISION INDUSTRIAL VACUUM CLEANER ACCESSORIES

The classification filters for vacuum cleaner and powders emissions into the environment, is assigned by the type of powders and the degree of danger to health. For its suction devices such classification is regulated by IEC 60335-2-69 worldwide. This classification provides several categories of powders, such as: • Category of powders L (low/moderate): fall into that category powders with MPC values (maximum permitted concentration in the work place) > 1 mg / m³Are retained at least 99% of particles aspirated.The disposal of the collected material must be made trying to raise a few powders. • Category of powders M (medium): fall into that category powders with MPC values (maximum permitted concentration in the work place) > 0.1 mg / m³ and wood powdersAre retained at least 99.9% of particles aspirated.The disposal of the collected material must be made trying to raise a few powders. • Category of powders H (high): fall into that category powders with MPC values (maximum permitted concentration in the work place) < 0.1 mg / m³, with carcinogenic and pathogenic powdersAre held at least 99.995% of particles aspirated.The disposal of the collected material must be done without raising powders. On each iVision vacuum cleaner is applied a label indicating the hazard class of the dust in the environment allowed. -

FLAT TABLE 100

Flat Table LineINDUSTRIAL VACUUM CLEANERS FOR CHIP ON CNC ROUTER

The industrial vacuum cleaners of the iVision FLAT TABLE 100 line are the best-selling models for use in the world of panel processing. Although compact in size, the FLAT TABLE 100 vacuum cleaners have a 100-liter tank to facilitate ease of use even in confined spaces. This means that they lend themselves to being mated to 3-axis milling machines that generate an important quantity of scraps and material to be vacuumed to guarantee a perfect end-product. -

FLAT TABLE 160

Flat Table LineINDUSTRIAL VACUUM CLEANERS FOR CHIP ON CNC ROUTER

The vacuum cleaners of the FLAT TABLE 160 line are the best performing models in the iVision range and are ideal for collecting chips in large CNC machines. Thanks to the powerful side channel blowers and the large chip collector (160lt), the FLAT TABLE 160 line vacuum cleaners are ideal for the maintenance and cleaning of large machining centers with high production of scraps, shavings and dust. The scraps generated by the cutters on 3-axis numerical control machines require industrial extraction of chips and dust as efficiently as possible, to ensure that the router works accurately and correctly. The integration of accessories specifically made for this sector, such as the innovative aerial arm, allows iVision to be able to provide the right product for each application. The use of highly technological components combined with meticulous care and attention to design characterize all iVision industrial vacuum cleaners. -

FLAT TABLE 320

Flat Table LineINDUSTRIAL VACUUM CLEANER FOR CHIP ON CNC ROUTER.

The FLAT TABLE 320 model is used in the world of machining with 3-axis CNC machines with high dust/chip production. Designed specifically for industrial purposes, this model is equipped with powerful motors and advanced performing filtration system. Its vacuum and airflow characteristics make it ideal for heavy dust extraction. The use of a pre-filter-cyclone enables it to capture more than 90% of the sucked material before it reaches the main filter, thus preventing clogging and greatly extending its service life. -

FLAT TABLE 38

Flat Table LineINDUSTRIAL VACUUM CLEANERS FOR CHIP ON CNC ROUTER

The vacuum cleaners of the FLAT TABLE 38 line are the most compact and practical models among the iVision range. These are industrial vacuum cleaners with side channel blowers, used for the collection of chips in small CNC machines. The waste generated by the 3-axis milling machines requires very efficient industrial extraction of chips in order to guarantee absolute cleanliness. The compact dimensions allow the operator to move with agility in confined spaces and the excellent performance of the side channel blowers is thus fully exploited. -

FREQUENCY INVERTER

AccessoriesIVISION INDUSTRIAL VACUUM CLEANER ACCESSORIES

Compact technology, powerful and built-to-last this characterizes the frequency inverter that regulates and manages the performance of iVision vacuums. The inverter operates the normal work of the turbines or intervenes instantaneously in all of the possible emergencies that may occur by increasing or decreasing the RPM of the engines in order to ensure the same performance for the system even in the case that a machine that the vacuum is attached to stops working. -

GATE CLOSURE

AccessoriesIVISION INDUSTRIAL VACUUM CLEANER ACCESSORIES

The gate valves that enable the closure of multiple vents allow the operator to choose to work with one, two or more hoses simultaneously. These gates can be operated manually by operators, handled automatically by machines, or remotely via foot pedal. -

HEPA FILTER

AccessoriesIVISION INDUSTRIAL VACUUM CLEANER ACCESSORIES

HEPA is the acronym used for the definition “High Efficiency Particulate Air”. It ‘a kind of filter for vacuum cleaner with a particular system of filtering with high efficiency for fluid, liquid or gas. It has the ability to trap a very high amount of particles of very small size, ability that other filters for vacuum cleaners do not have. Indeed, there are different categories of filters (L / M / H), and different categories of HEPA filters, that has made according to the material more efficient to inhale. The HEPA filter is composed from microfiber filter sheets (generally borosilicate) assembled in multiple layers, and separated by aluminum septa. The microfiber filter sheets have the task to block the polluting solid particles (or particulate). The solid particles are very small and can be harmful to health or may affect the quality of the final product to be obtained. HEPA filters are part of the category of the “absolute filters”, justified by the fact that these filters have a high efficiency of filterign. In particular, HEPA filters introduce an efficiency of filtering between 85% (H10) and 99.995% (H14). The filtration efficiency of particles of 0.3 µm, is regulated by the UNI EN 1822. -

LIFT KIT

AccessoriesIVISION INDUSTRIAL VACUUM CLEANER ACCESSORIES

The lifting device is used for emptying the 100 Lt (iV2 model) or the 160 Lt (iV3 model) chip container with the use of a forklift. The operators do not have to make any effort for the emptying process. At the sides of the collecting containers there are two hooks for the lifting kit to be connected to, which in turn is lifted from the truck by a chain. -

OIL MIST 600

Oil MistINDUSTRIAL VACUUM CLEANERS FOR OIL MIST

Designed for the suction and purification of air from oily mists and fumes, the OIL MIST 600 model is ideal for connecting to machines for the processing of small components. This model is intended for use with work stations, lathes and machine tools with an internal volume > 1 m3 and with lathing machines with oil injectors < 20 mm. The main cartridge filter, made of glass microfibre together with the microfibre prefilter inside a metal cell, guarantees filtration with an efficiency of 99%. -

PCB 100

PCB LineINDUSTRIAL VACUUM CLEANERS FOR FIBERGLASS AND ALUMINIUM

The 100 vacuum cleaners of the PCB line are specifically designed for industrial purposes and this model is equipped with a powerful side channel blower and a cutting-edge filtering system. The characteristics of negative pressure and air flow make the 100 ideal for the intensive collection of chips and heavy dust generated by drilling and milling machines with 2 to 6 spindles. This innovative range of industrial vacuum cleaner models is used with great success in the world of printed circuit board manufacturing in Europe, the United States and Asian countries. Thanks to the latest technologies available on the 100 units of the PCB line, the waste generated on drilling or milling machines is efficiently collected during processing to guarantee an impeccable final product. In addition to the wide range of side channel blowers, iVision has also created and patented a series of specific accessories for the PCB world that can be associated with the 100 line, making our units the ideal and indispensable solution for every manufacturing workshop of PCBs. -

PCB 160

PCB LineINDUSTRIAL VACUUM CLEANERS FOR FIBERGLASS AND ALUMINIUM

The 160 vacuum cleaners of the PCB line are the most powerful of the wheeled vacuum cleaners and are used for the collection of shavings and dust in CNC drilling and large milling machines (6-8 spindles). These industrial vacuum cleaners can be used, in their customized version, also with frequency inverters and can be transformed into real centralized systems. Both in Europe and in the United States, the iVision PCB 160 vacuum cleaners have been chosen thanks to their performance, versatility and customization they guarantee a processing free of chips and dust and therefore an impeccable final product. iVision has designed, produced and patented a series of specific accessories for the printed circuit industry such as the touch screen and the HMI (Human Machine Interface) ideal and indispensable for large plants of PCB manufacturing. -

PCB 320

PCB LineINDUSTRIAL VACUUM CLEANER FOR FIBERGLASS AND ALUMINIUM

The iVision vacuum cleaners of the PCB 320 line consist of a cyclonic prefilter, a central unit with side-channel blower, an integrated filter, an electrical panel complete with inverter and all the necessary components in the PLC management control with color touch screen. The system is also equipped with a powerful silencer to ensure full compliance with international standards. The PCB Custom vacuum cleaners are centralized systems among the most technologically advanced available on the market, and cannot be compared to any of the traditionally known systems. The long experience of the iVision staff, as well as the desire to satisfy customer requests, have led to the development of high-tech products and customized solutions. Thanks to a frequency inverter, the vacuum cleaners of the PCB Custom line can manage many CNC machines with the same efficiency simultaneously. A sophisticated control sensor (optional) is able to measure the efficiency of the filter of the vacuum cleaners, considerably reducing maintenance and guaranteeing constant performance and durable centralized suction. -

PCB 38

PCB LineINDUSTRIAL VACUUM CLEANERS FOR FIBERGLASS AND ALUMINIUM

The 38 vacuum cleaners of the PCB line are the most compact of all iVision industrial vacuum cleaners and are typically used for the collection of chips and dust in small machines with one or two spindles. The compact dimensions and the low noise level allow the worker to operate in small and cramped places with agility and practicality, favoring positioning even in environments with limited spaces. Efficiency, ease of use and maintenance, as well as the design and use of Italian components are the fundamental characteristics of iVision’s industrial vacuum cleaners. In addition to the wide range of side channel blowers, iVision has also created and patented a series of specific accessories for the PCB world that can be associated with the 38 line, making our units the ideal and indispensable solution for every manufacturing workshop of PCBs. -

PCB CUSTOM

PCB LineINDUSTRIAL VACUUM CLEANER FOR FIBERGLASS AND ALUMINIUM

The vacuum cleaners of the PCB line are dedicated to machines for the production of printed circuits such as drilling, milling or contouring machines, which require accurate and efficient extraction of chips/dust. The CUSTOM model features a continuous discharging system with rotary valve that discharges the material directly into bigbags. The detection sensors and the sound and visual alarm system are designed to provide the operator with the maximum support. The separate 4-independent cartridge cleaning system allows maximum efficiency at all times. iVision© HMI system allows full control of the system and its efficiency, easily and intuitively. -

REMOTE START & STOP

AccessoriesIVISION INDUSTRIAL VACUUM CLEANER ACCESSORIES

The kit allows the automatic switching on and off of the vacuum cleaner simultaneously with the machine tool when they are connected. This can occur in three different ways: a) The vacuum gets switched on by contact without electricity "potential free contact". b) The vacuum gets switched on with a 24V contact. c) The vacuum gets switched on with a 230V contact. -

SAND 100

Sand LineINDUSTRIAL VACUUM CLEANERS FOR SAND

The industrial vacuums of the Sand 100 line are used for dust and sand grit collection in industrial environments. iVision has developed a range of industrial vacuum cleaners with side channel blower, with reinforced plates dedicated to the world of industrial sandblasting. Thanks to their compact 100-liter collection capacity, the 100 industrial vacuum cleaners of the SAND Line allow the operator to move with agility in tight environments. The SAND 100 will make more agile every type of processing as well as safeguard the health of operators and working environments where powders and grits are constantly produced by sandblasters. In addition to its vacuum cleaners, iVision has also created and patented many accessories dedicated to the world of sandblasting, which allow each customer to use a product tailored to their needs. -

SAND CUSTOM

Sand LineINDUSTRIAL VACUUM CLEANERS FOR SAND

The vacuum cleaners in the SAND line are created to fulfil specific CUSTOMER requests. iVision has developed centralised suction systems with the continuous discharging system with rotary valve that operates continuously and discharges the material directly into containers housed inside the box (a big bag, a contained or your sandblaster). The System is built with heavy duty metalwork designed and tested specifically for intensive and special uses. This particular system makes it possible to position your sandblaster under the rotary valve, so that the material lands directly in it. It features a cyclonic pre-filter system for dedusting grits and discharging the heavy part into big bags/container/ sandblaster. An additional sieve to separate grit is set up to avoid too big particles from getting into the sandblaster. The separate 4-independent cartridge cleaning System allows maximum efficiency of the System at all times. iVision© touch screen system allows full control of the system and its efficiency in an easy and intuitive way. -

SAND TR

Sand LineINDUSTRIAL VACUUM CLEANERS FOR SAND

The TR vacuum cleaners, from the Sand line, are used for the collection of dust and sand-blasting in industrial environments, where efficient extraction is required in order to keep the working environment clean and the operators’ health protected. The collection hopper allows the material to be stored and the manual valve at the base facilitates its discharge directly into the sandblaster by moving the vacuum cleaner via the lifting supports. -

SANDBLASTING CLEANING KIT

AccessoriesIVISION INDUSTRIAL VACUUM CLEANER ACCESSORIES

For office or the work environment at the end of the day cleaning, iVision has developed a cleaning kit particularly robust dedicated to the sandblasting world. This version can be enlarged according to the specific needs of the client and can be easily attached through special supports on the side of the vacuum, this also helps avoid the tube from impeding the vacuum movement. -

SHOES 160

Shoes LineINDUSTRIAL VACUUM CLEANER FOR DUST OF LEATHER & FABRICS

The vacuum cleaners of the Shoes 160 line are the best-selling iVision industrial vacuum cleaners in the world of footwear production. These are excellent systems used in the world of footwear for the industrial extraction of chips, dust or waste generated by grinding, carding or brushing machines. The vacuum cleaners of the Shoes 160 line cover almost all the suction needs of scraps on machine tools in the world of shoe production as well as leather and fabric processing by combining the attention and care of design with simple and robust materials. The experience in this sector has led iVision to develop increasingly effective and safe suction systems to ensure continuous and always reliable processing. -

SHOES 320

Shoes LineINDUSTRIAL VACUUM CLEANER FOR DUST OF LEATHER & FABRICS

The SHOES 320 litres vacuum cleaner is an excellent system used in the shoemaking world for the industrial extraction of grinding, carding or brushing machines. Vacuum cleaners in the SHOES line basically cover all of the chip extraction needs on machine tools in the shoe production world and from leather and fabric processing, combining the attention and care of design with simple and sturdy materials. The use of a cyclonic pre-filter captures more than 90% of the suctioned material before it reaches the main filter, thus preventing it from clogging and considerably extending its life.