EXTRUSION 320

INDUSTRIAL VACUUM CLEANERS FOR METAL & PVC CHIPS

The 320 vacuum cleaners of the Extrusion line are designed specifically for industrial purposes, this model is equipped with powerful motors and an advanced filtering system.

Its vacuum characteristics and air flow rate make it ideal for the suction of chips or dust.

The use of a cyclonic pre-filter captures more than 90% of the suctioned material before it reaches the main filter, thus preventing it from clogging and considerably extending its life.

Category: Extrusion Line

OPTIONAL

- Antistatic kit

- Start & stop

- Touch screen

- Filter Cleaning System with piston (semi-automatic)

The vacuum cleaner can also be supplied with ATEX-Zone 22 certification for explosive atmospheres. More info

-

CLEANING KIT Ø 50 mm

AccessoriesIVISION INDUSTRIAL VACUUM CLEANER ACCESSORIES

The cleaning kit is usable on all of the series and consists of a robust, anti-abrasion tube that ends at the extremities with special zinc-plated steel accessories capable of transporting, without any obstacle, chippings and oil from the machine tool to the vacuum collection tank. The suction tube comes housed inside a support in order to facilitate the movement of the vacuum in the workshop without being an obstable for the operator, it allows the avoidance of leakage of oil during the maneuvers of the vacuum. -

ANTISTATIC KIT

AccessoriesIVISION INDUSTRIAL VACUUM CLEANER ACCESSORIES

To be applied to all models of industrial vacuums in production. This kit allows you to unload electrostatic charges accumulated during the collection phase, avoiding transferring them to other machinery or operators. It’s particularly recommended during the working of aluminum, considering the chips of this material can create a potentially explosive atmosphere inside of the tank. -

AUTOMATIC CLEANING WITH SHAKING

AccessoriesIVISION INDUSTRIAL VACUUM CLEANER ACCESSORIES

Filter cleaning with a pneumatic piston requires being connected to an air adapter from 6-8 bar and via a pressure regulator that can vary the intensity of the sliding of the piston. • To effectively clean the filters mounted inside the vacuum, the vertical piston filter cleaning system was developed. Through a manual selector (semiautomatic solution) or by a timer (automatic version) a pneumatic piston acts from the bottom of the filter, shaking it intensely in a way that ensures that the chips or the dust transferred to the outside of the filter fall into the collection tank, permitting in this way the continued optimal functioning of the filter. • Vertical piston cleaning of the filter is recommended for any type of application, as it significantly improves the cleaning of the filter compared to the vibrating motor standard version. • Vertical piston cleaning of the filter, especially in its automatic version, becomes mandatory in the suctioning of fine dust that can clog the filter rapidly. In the case of large and heavy chips, this system is not mandatory, but for light or volatile material, yes! • The principal advantage of this system comes from the greater efficiency in the incisiveness of the shaking of the filter with a piston. Another advantage is the use of this system in its automatic version, shaking the filter every time that the motor is turned off, eliminating the typical problem of the reliability of the operator, who usually has to remember to turn on the cleaning of the filter. -

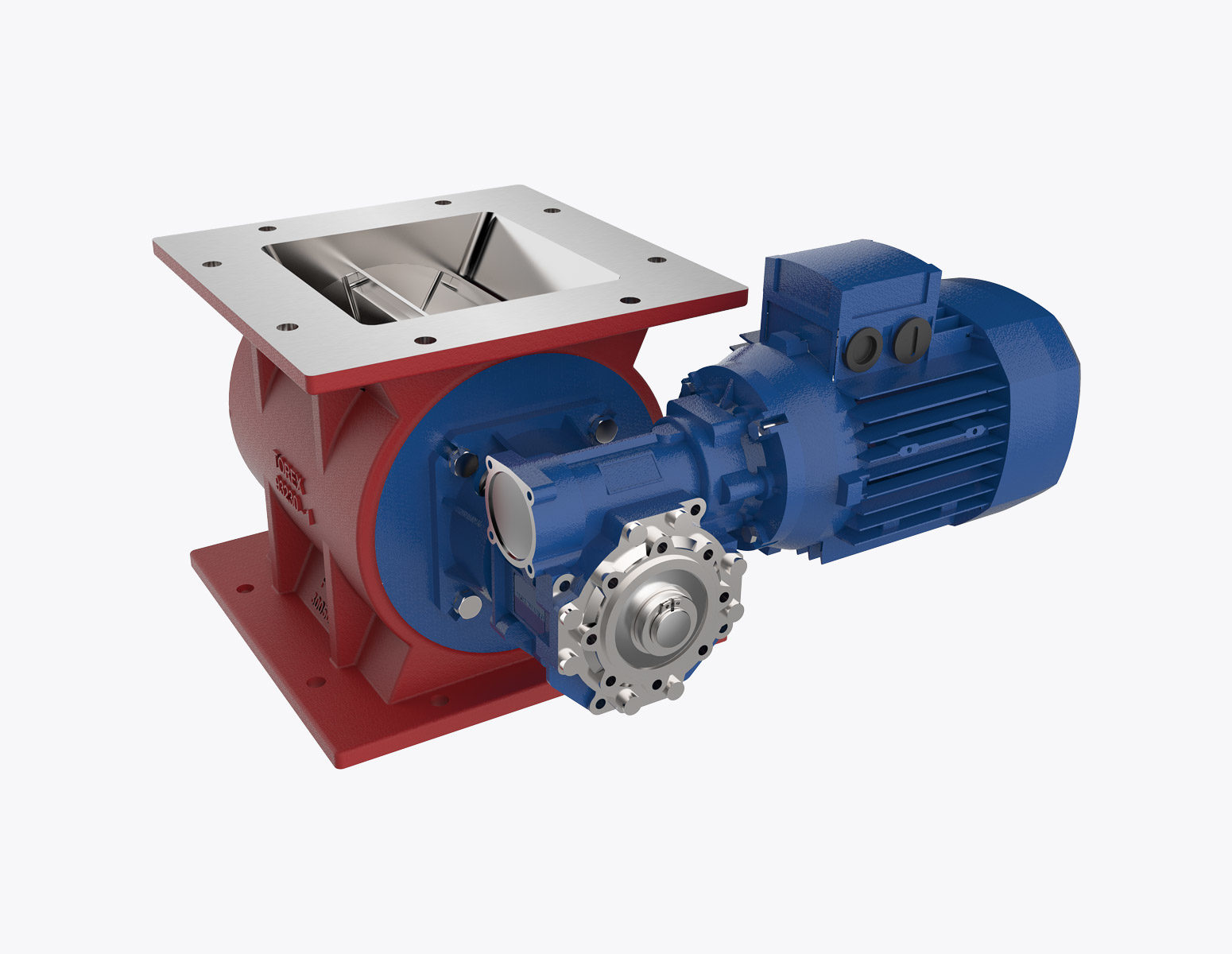

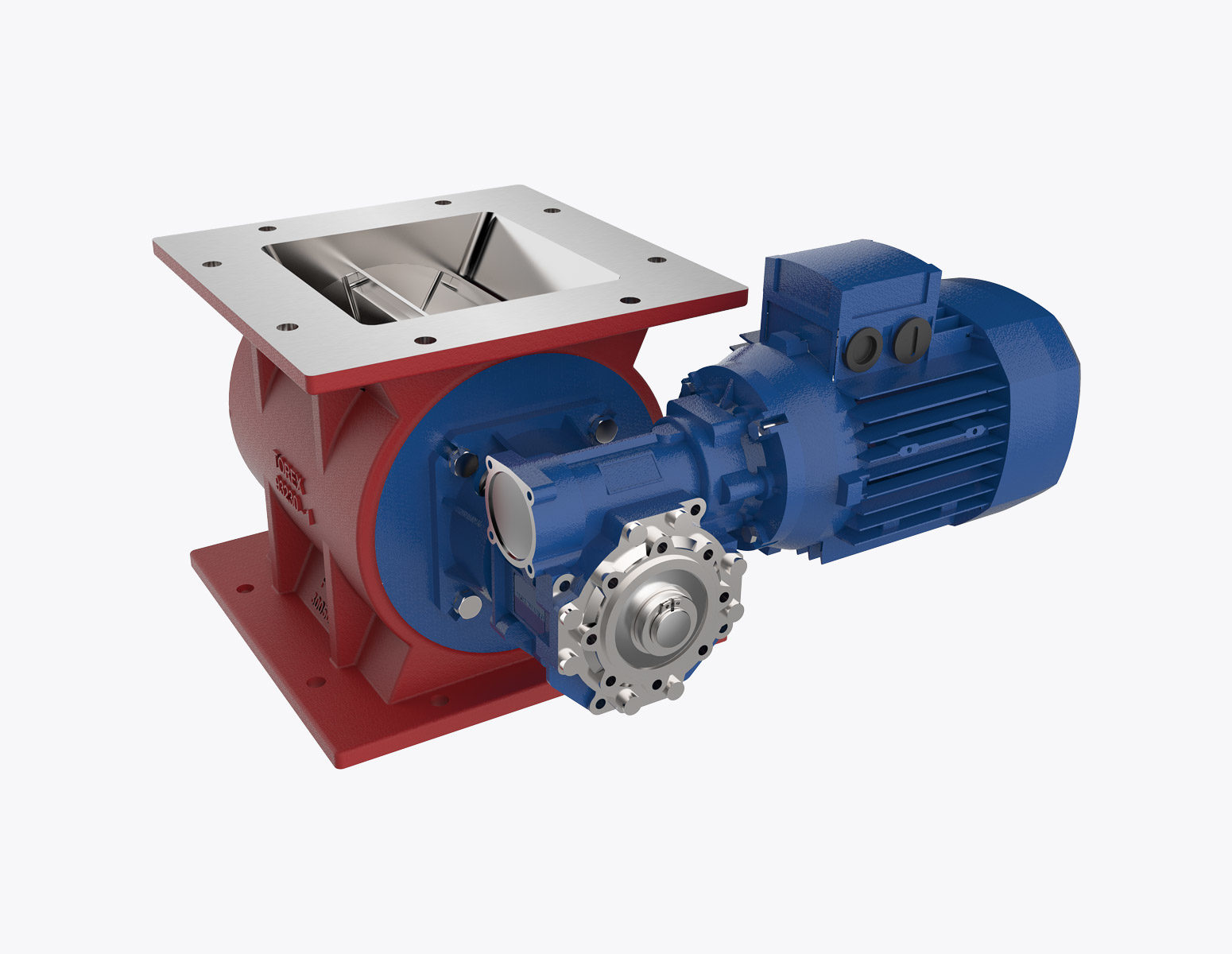

EMPTYING ROTARY VALVE KIT FOR CONTINUOUS WORK

AccessoriesHI-TECH VACUUM

For those that need a continuous work cycle in construction environments and need to empty without interrupting work due to turning off the vacuum to empty the collection container, the iVision rotary valve kit is an interesting solution. -

REMOTE START & STOP

AccessoriesIVISION INDUSTRIAL VACUUM CLEANER ACCESSORIES

The kit allows the automatic switching on and off of the vacuum cleaner simultaneously with the machine tool when they are connected. This can occur in three different ways: a) The vacuum gets switched on by contact without electricity "potential free contact". b) The vacuum gets switched on with a 24V contact. c) The vacuum gets switched on with a 230V contact. -

GATE CLOSURE

AccessoriesIVISION INDUSTRIAL VACUUM CLEANER ACCESSORIES

The gate valves that enable the closure of multiple vents allow the operator to choose to work with one, two or more hoses simultaneously. These gates can be operated manually by operators, handled automatically by machines, or remotely via foot pedal. -

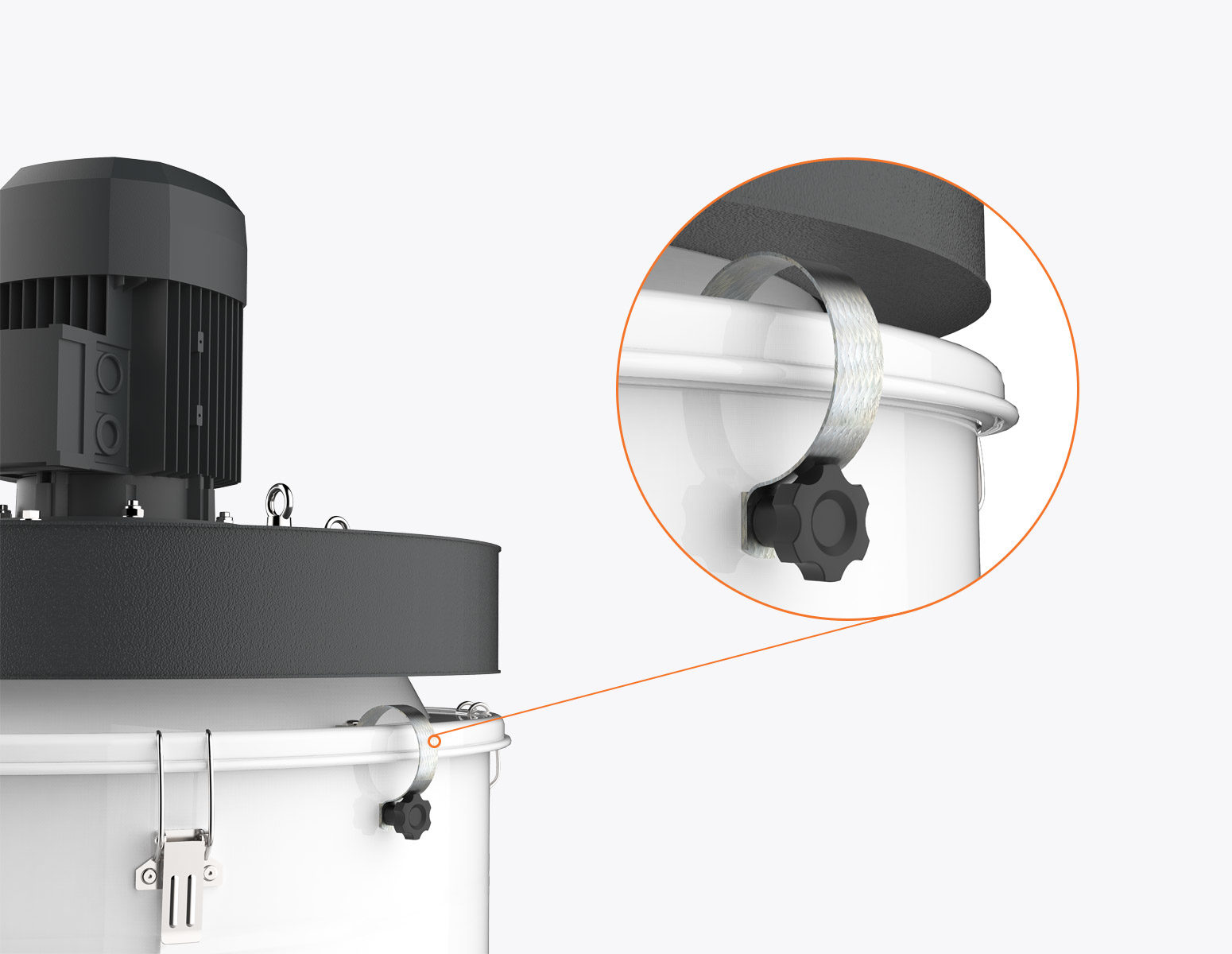

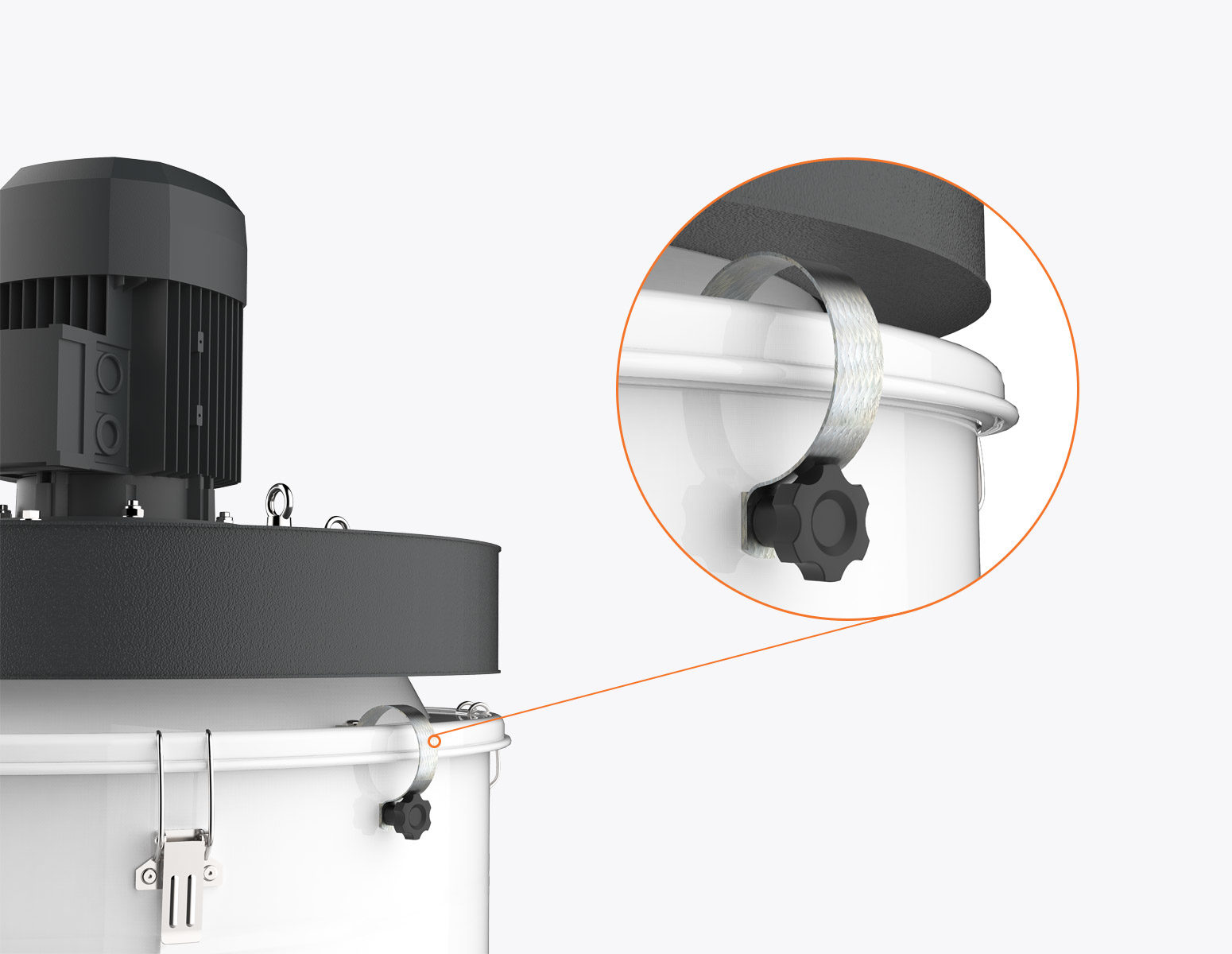

CYCLONIC PREFILTER

AccessoriesIVISION INDUSTRIAL VACUUM CLEANER ACCESSORIES

Strongly recommended whenever possible, the pre-filter is positioned between the vacuum and the chip-generating machine, as the first point of collection of the collected material. It is specially used to preserve the life of the filter inside the vacuum unit. It retains most of the collected material and can have a cone or cylindric shape and serves as a mechanical filter. Through a tangential entry the collected material is centrifuged into its interior until its speed gradually decreases and the material gradually falls to the bottom of the collecting unit due to the force of gravity. Such a process ensures that only a relatively low percentage of collected dust or chips manages to actually reach the real filter positioned in the upper part of the vacuum cleaner. The cyclonic pre-filter can be combined with a: • 160 L tank • 500 L tank • 1000 L tank The cyclonic pre-filter becomes almost mandatory for fine or very fine powders, which are very likely to clog the filter quickly, compromising the smooth operation of the entire system, but are only recommended for large, heavy chips. The main advantage of the cyclonic pre-filter is to protect the filter of the vacuum cleaner from quickly clogging, thus extending its life before replacement and significantly reducing the maintenance of the entire system. -

ADDITIONAL DUMPSTER

AccessoriesIVISION INDUSTRIAL VACUUM CLEANER ACCESSORIES

In the case that the vacuum cleaner standard capacity 42 Gal is not enough, iVision offers its customers additional high-capacity chip containers. Ivision has developed 2 types of dumpsters: A) 1000 Lt dumpster with automatic opening B) 500 Lt dumpster with manual opening The dumpsters are equipped with a visual filling indicator that shows the operator when it is time to empty the container. -

TOUCH SCREEN

AccessoriesIVISION INDUSTRIAL VACUUM CLEANER ACCESSORIES

The vacuum cleaner is equipped with a touch screen unit on the front. It allows the operator to quickly and easily monitor the level of contamination of the filter. Thanks to such a device, the operator is able to recognize in real time the filter condition and the efficiency of the whole vacuum cleaner. Afterwards, the operator can choose to clean the filter (in manual or automatic mode) and also manage the remote Start&Stop control option. Once the filter is completely clogged, the unit will automatically warn the operator of the need to replace the filter utilizing: • An audible signal. • A visual signal.

EXTRUSION 1000

Extrusion LineINDUSTRIAL VACUUM CLEANERS FOR METAL & PVC CHIPS

EXTRUSION 1000 litres is ideal for use in combination with doublehead saws or automatic cutting centres with high chip and dust production. This model features:- a cyclone pre-filter that captures more than 90% of the extracted material before it reaches the main filter

- a 1000-litre container with pneumatic opening and practical tipping unloading system

EXTRUSION 160

Extrusion LineINDUSTRIAL VACUUM CLEANERS FOR METAL & PVC CHIPS

The 160 vacuum cleaners of the Extrusion line are the best-selling iVision models thanks to their versatility. These excellent systems are used alongisde double-head saws or automatic cutting centers with a high production of chips and dust. Thanks to the wide range of industrial vacuums and the almost infinite possibility of customization, iVision is able to satisfy all the suction needs on machine tools in the extrusion world by combining the use of robust materials, the great construction care and the attention given to the design. The 160 are the vacuum cleaners chosen by those who demand the best in terms of performance, efficiency and innovation in the workplace.

EXTRUSION 100

Extrusion LineINDUSTRIAL VACUUM CLEANERS FOR ALUMINIUM & PVC CHIPS

The 100 vacuum cleaners of the Ivision Extrusion line are used together with large single-head saws or small double-head saws. These highly versatile industrial vacuums find their ideal application in manufacturers of PVC or aluminum windows where the characteristics of the powerful centrifugal fans can be exploited to the maximum. The use of robust materials, the great construction care and the attention given to the design have allowed these vacuum cleaners to establish themselves in the world of extrusion and window frames where iVision is recognized as synonymous with quality, reliability, innovation and efficiency.