The processing of ferrous and non-ferrous materials, such as aluminium and titanium, on grinding benches generates fine dust that poses significant risks to operator safety and the quality of the working environment. While workbenches often include built-in extraction systems, these are frequently inadequate for capturing fine particles, leaving room for potential hazards.

In this article, we will explore the importance of customized vacuum solutions, focusing on two custom vacuum systems developed by iVision Vacuum to effectively handle fine metal dust generated during grinding operations.

The DUSTFREE line of iVision Vacuum for fine metal powders

To address the challenges faced by clients dealing with fine metal dust on grinding benches, iVision Vacuum proposed the DUSTFREE line. These industrial vacuum cleaners are distinguished by their ability to treat dry and fine dust directly at the source, ensuring localised suction and effective air purification.

For this particular project, the DUSTFREE 160 was customized to guarantee maximum operational efficiency and seamless integration with the client’s production processes.

The features of the DUSTFREE 160 CUSTOM for the customer

The customer needed a system that could effectively handle the fine metal dust produced during grinding, while ensuring seamless integration with existing workbenches and compliance with ATEX regulations. In addition, the system had to improve operational safety, reduce noise and optimise energy consumption.

Our DUSTFREE 160 was specifically designed to integrate seamlessly with existing grinding benches, while ensuring a significant improvement in safety and operational efficiency.

Here are the key customisations:

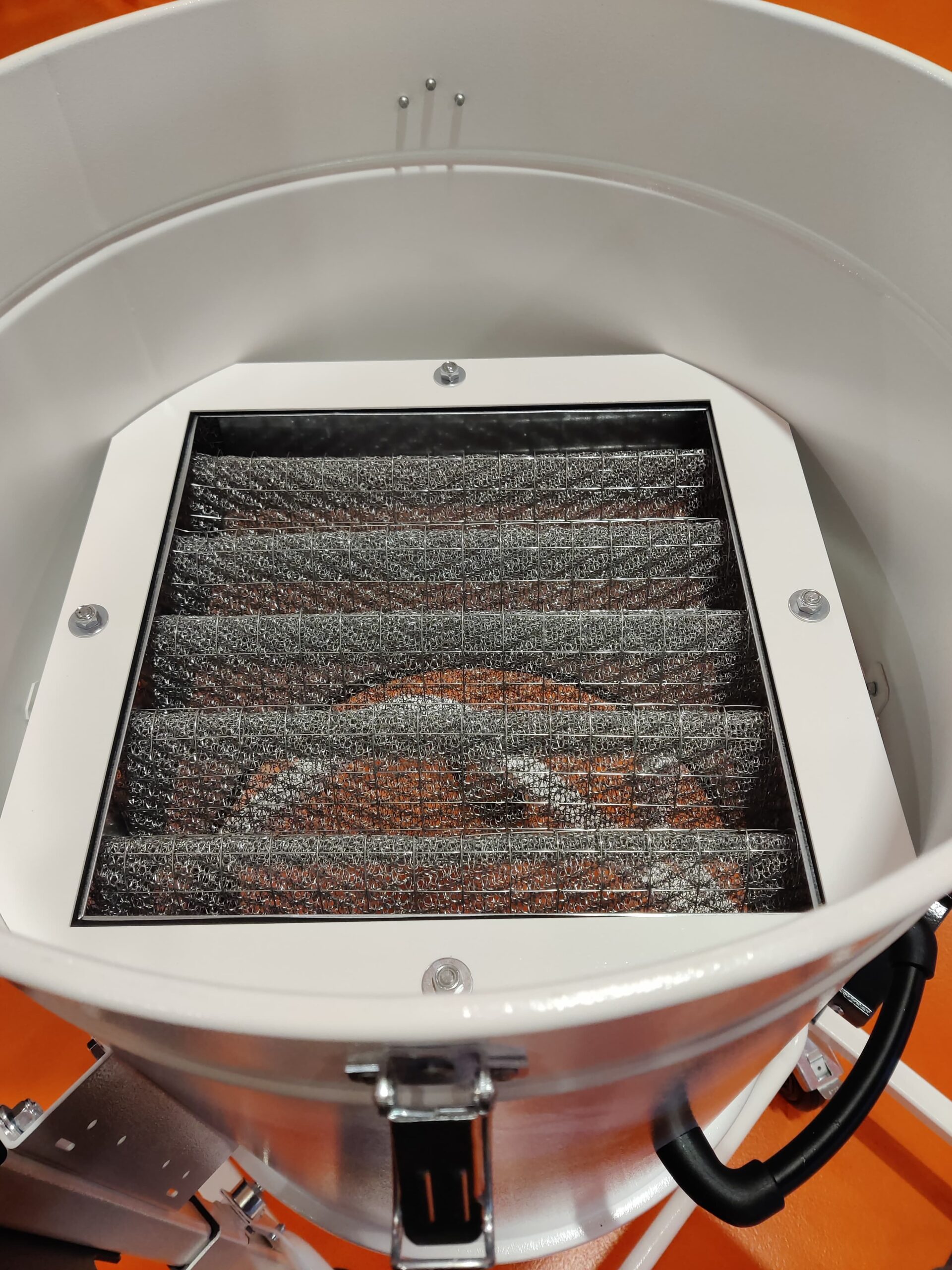

METAL ANTI-SPARK FILTER SYSTEM

During metal grinding, the formation of incandescent dust is common. Our filter system includes an anti-spark module, a necessary protection to prevent potential fires and ensure safe operation, especially in the presence of metal dust.

MANUAL FILTER CLEANING SYSTEM

To ensure optimal performance over time, our vacuum cleaner is equipped with a manual filter cleaning system that easily removes accumulated dust, increasing the efficiency of the vacuum system and reducing the need for frequent maintenance.

ATEX TELESCOPIC SUCTION ARM

The vacuum cleaner is fitted with an adjustable telescopic suction arm, designed in accordance with ATEX Zone 22 regulations. This feature provides exceptional flexibility and mobility, allowing precise suction directly at the source of dust or fumes. It ensures the safety of operators working in hazardous conditions by effectively capturing contaminants at their origin.

EXCEPTIONAL SILENCE

A critical requirement from the customer was to minimize noise levels, significantly improving operational comfort. This version of the vacuum cleaner operates at an impressively low noise level of 72 dB(A), making it a highly suitable option even for sensitive or noise-restricted working environments.

ATEX CENTRIFUGAL FAN

The incorporation of a centrifugal fan certified for ATEX Zone 22 compliance ensures the system’s suitability for environments with potentially explosive atmospheres. These conditions are often encountered during the grinding or welding of metallic materials, where safety is paramount.

TANGENTIAL INLET

The vacuum cleaner is engineered with a tangential inlet, which enhances air intake efficiency by minimizing vortex formation. This design optimizes airflow distribution, resulting in improved performance and reduced energy consumption. The tangential inlet is particularly advantageous during prolonged operations or in work environments with intensive dust production.

VERSATILITY AND INTEGRATION WITH ADVANCED SYSTEMS

The DUSTFREE 160 is highly versatile and can be equipped with optional HEPA and activated carbon filters. This adaptability extends its applications to include the extraction of welding fumes, solvent vapors, and hazardous particles. The HEPA filters are capable of capturing ultra-fine particles down to 0.3 microns, while the activated carbon filters neutralize chemical compounds and odors, ensuring clean and purified air is released back into the environment.

OTHER FEATURES

To find out in detail all customisation possibilities and other technical features please contact us.

Do you need a customized vacuum solution for your company?

Every industry has specific needs. At iVision Vacuum, we specialize in designing customized vacuum systems that prioritize safety, efficiency, and seamless integration. Contact us for a dedicated consultation and find out how we can develop the perfect vacuum cleaner for your needs!