48.000 liters in 8 hours is equivalent to 5 liters per minute: this is the amount of air that an operator breathes during the work day. The harmful substances produced during the processing of material are absorbed into the body through the skin and lungs.

Less oxygen means more physical effort and a higher risk of accidents and diseases specific to the work environment.

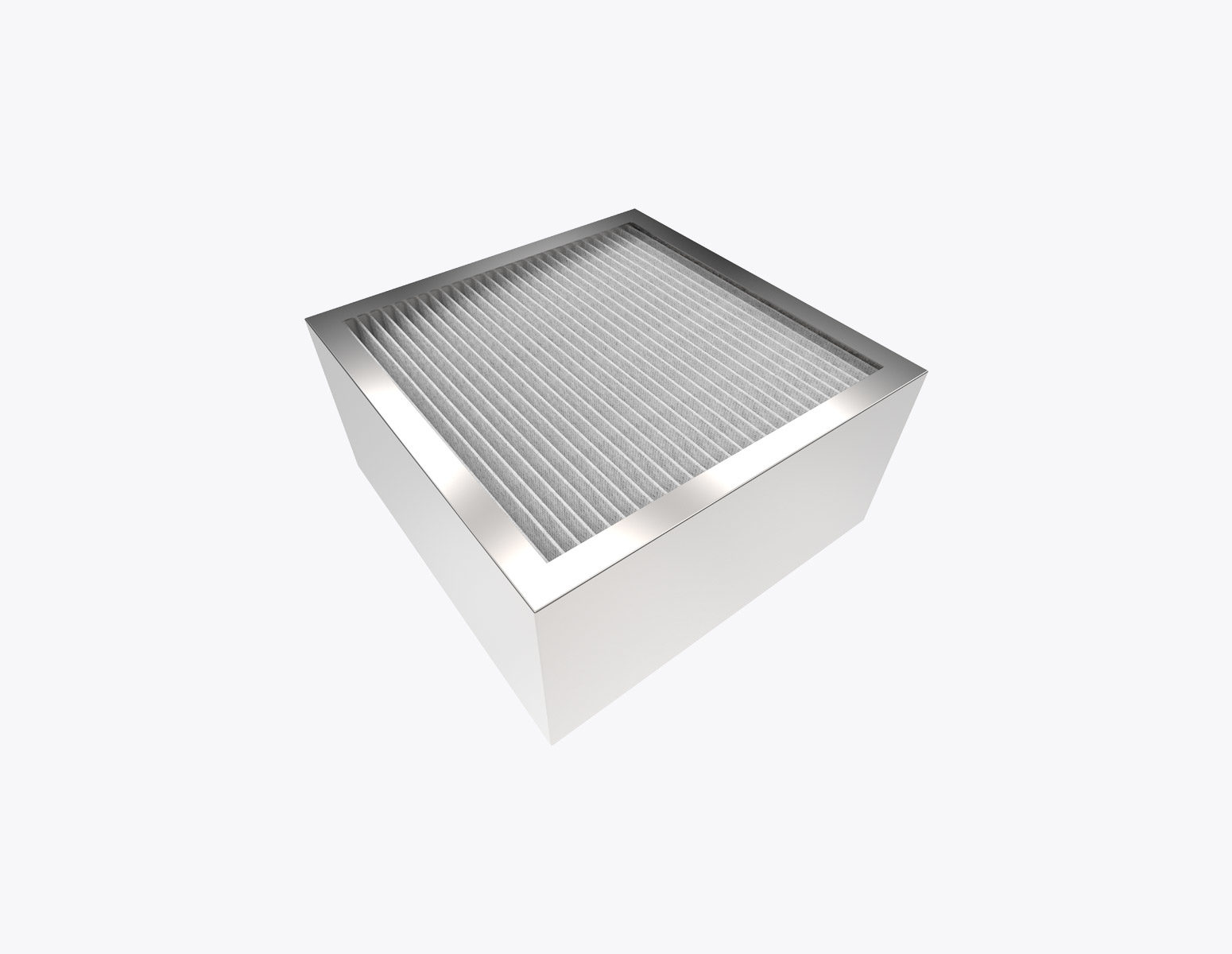

Quality of health as a result needs to rely on a suction device capable of collecting the harmful particles during and after processing. Choosing iVision puts your health at safety with mac-standard machines or customized ventilation systems capable of ventilating the contaminated air outside of the work environment.

Do not settle, choose iVision!