-

OIL MIST 1000

Oil MistASPIRADORES INDUSTRIAIS PARA NÉVOA DE ÓLEO

Concebido para a aspiração e purificação do ar de névoas e fumos oleosos, o modelo OIL MIST 1000 é ideal para ligação a máquinas de processamento de pequena e média dimensão. Este modelo destina-se a ser ligado a postos de trabalho, tornos e máquinas-ferramentas com um volume interno > 3 m3 e a tornos com injectores de óleo = 20 mm. O filtro de cartucho principal, feito de microfibra de vidro, juntamente com o pré-filtro de microfibra dentro de uma célula metálica, garante uma filtragem com uma eficiência de 99%. -

OIL MIST 1500

Oil MistASPIRADORES INDUSTRIAIS PARA NÉVOA DE ÓLEO

Concebido para a aspiração e purificação do ar de névoas e fumos oleosos, o modelo OIL MIST 1500 é ideal para ligação a máquinas de processamento de componentes mais complexos. Este modelo destina-se a ser ligado a estações de trabalho, tornos e máquinas-ferramentas com um volume interno > 6 m3 e a máquinas de torneamento com injectores de óleo= 30 mm. O filtro principal de cartucho de microfibra de vidro, juntamente com o pré-filtro de microfibra dentro de uma célula metálica, garante uma filtragem com uma eficiência de 99%. -

OIL MIST 2000

Oil MistASPIRADORES INDUSTRIAIS PARA NÉVOA DE ÓLEO

Concebido para a aspiração e purificação do ar de névoas e fumos oleosos, o modelo OIL MIST 2000 é ideal para ligação a máquinas de processamento de componentes mais complexos. Este modelo destina-se a ser ligado a postos de trabalho, tornos e máquinas-ferramentas com um volume interno > 12 m3. O filtro principal de cartucho de microfibra de vidro, juntamente com o pré-filtro de microfibra dentro de uma célula metálica, garantem uma filtragem com uma eficiência de 99%. -

DEPÓSITO ADICIONAL

AccessòriosACESSÓRIOS PARA ASPIRADORES INDUSTRIAIS IVISION

Caso a capacidade standard do aspirador de 42 Gal não seja suficiente, a iVision oferece aos seus clientes contentores adicionais de alta capacidade para aparas. A iVision desenvolveu 2 tipos de contentores de lixo: A) Contentor de lixo de 1000 litros com abertura automática B) Contentor de lixo de 500 litros com abertura manual Os contentores estão equipados com um indicador visual de enchimento que mostra ao operador quando é altura de esvaziar o contentor. -

BRAÇO DE APOIO

AccessòriosACESSÓRIOS PARA ASPIRADORES INDUSTRIAIS IVISION

O braço aéreo é altamente recomendado para todas as fresadoras CNC. A utilização deste sistema reduz o risco de acidentes devido à obstrução do tubo nas laterais da máquina. -

KIT DE COMBATE A INCÊNDIOS

AccessòriosACESSÓRIOS PARA ASPIRADORES INDUSTRIAIS IVISION

Este acessório é um dispositivo que intervém automaticamente no caso de haver um aumento consistente da temperatura no interior do depósito de recolha, esvaziando uma mistura de ar e água no interior do depósito através de um bocal de pulverização. No caso de o sistema não ser ativado automaticamente, é possível activá-lo manualmente utilizando o botão apropriado. -

KIT ANTISTÁTICO

AccessòriosACESSÓRIOS PARA ASPIRADORES INDUSTRIAIS IVISION

Aplicable a todos los modelos de aspiradores industriales en producción. Este kit permite descargar las cargas electrostáticas acumuladas durante la fase de recogida, evitando transferirlas a otras máquinas u operarios. Es especialmente recomendable durante el trabajo del aluminio, teniendo en cuenta que las virutas de este material pueden crear una atmósfera potencialmente explosiva en el interior de la cuba. -

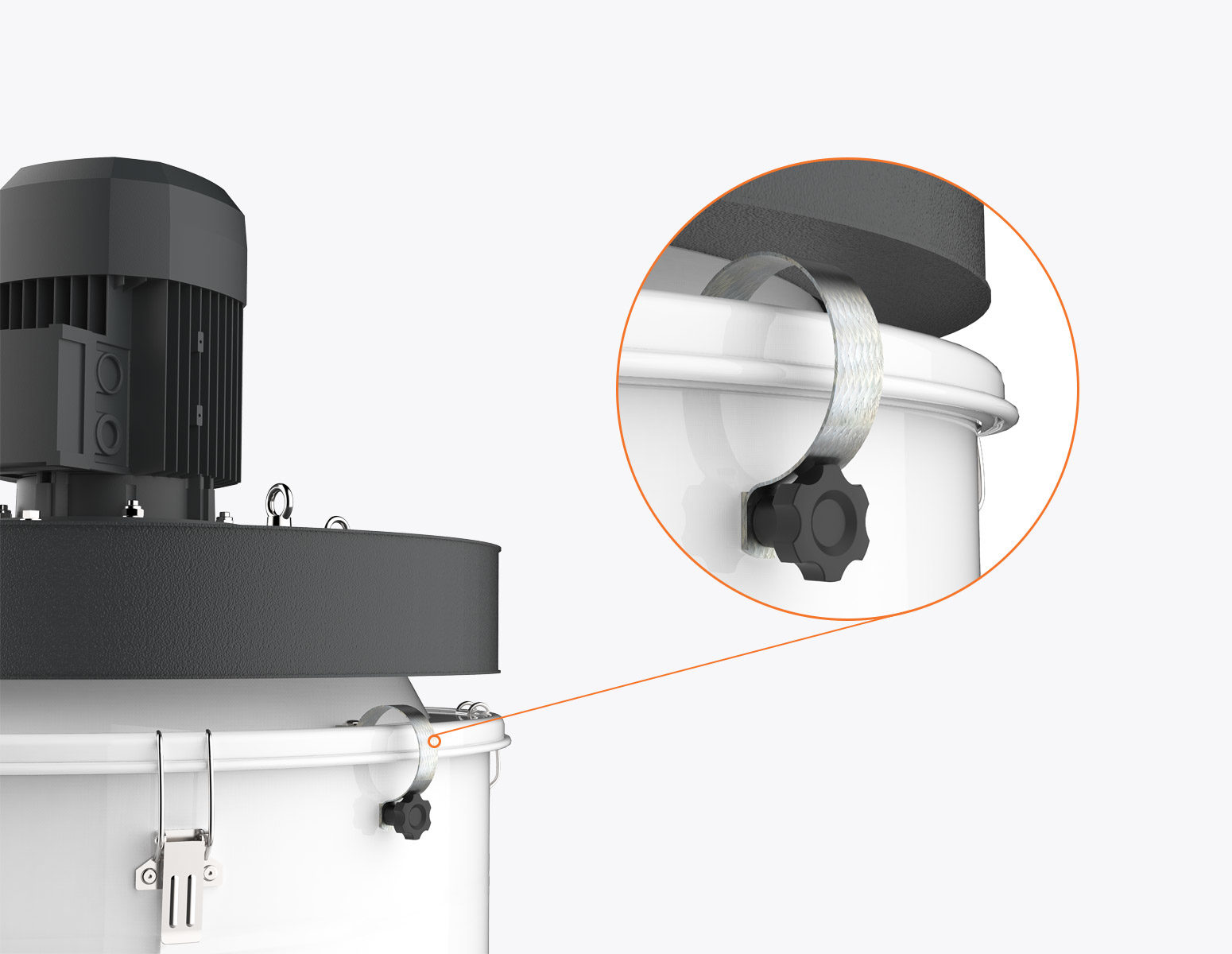

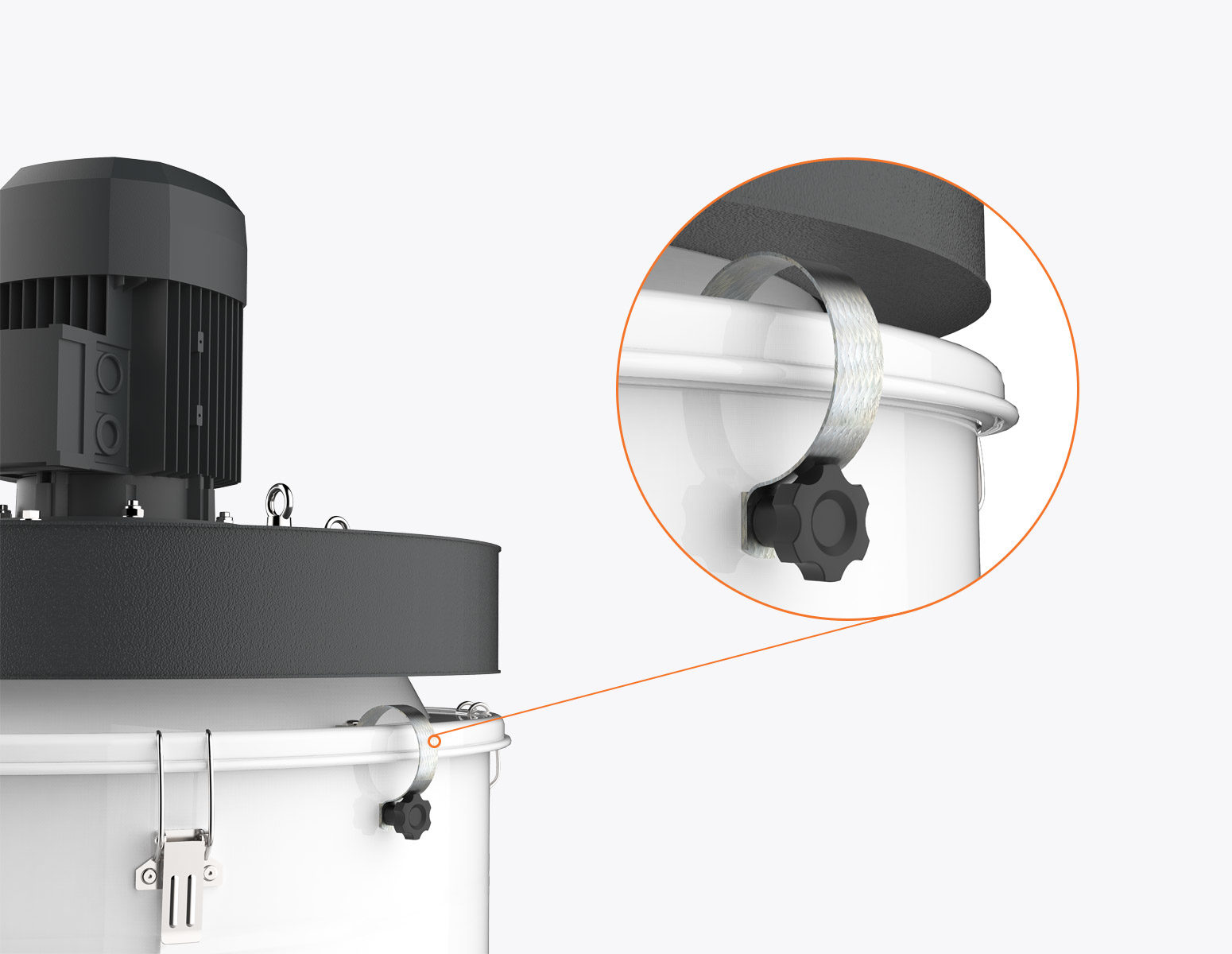

LIMPEZA AUTOMÁTICA COM AGITAÇÃO

AccessòriosACESSÓRIOS PARA ASPIRADORES INDUSTRIAIS IVISION

A limpeza de filtros com um pistão pneumático requer a ligação a um adaptador de ar de 6-8 bar e através de um regulador de pressão que pode variar a intensidade do deslizamento do pistão. - Para limpar eficazmente os filtros montados no interior do vácuo, foi desenvolvido o sistema de limpeza de filtros com pistão vertical. Através de um seletor manual (solução semi-automática) ou de um temporizador (versão automática), um pistão pneumático actua a partir da parte inferior do filtro, agitando-o intensamente de forma a garantir que as aparas ou o pó transferido para o exterior do filtro caiam no depósito de recolha, permitindo assim a continuação do funcionamento ótimo do filtro. - A limpeza do filtro com pistão vertical é recomendada para qualquer tipo de aplicação, uma vez que melhora significativamente a limpeza do filtro em comparação com a versão standard com motor vibratório. - A limpeza vertical do filtro por pistão, especialmente na sua versão automática, torna-se obrigatória na aspiração de poeiras finas que podem entupir o filtro rapidamente. No caso de aparas grandes e pesadas, este sistema não é obrigatório, mas para material leve ou volátil, sim! - A principal vantagem deste sistema advém da maior eficácia na incisividade da agitação do filtro com um pistão. Outra vantagem é a utilização deste sistema na sua versão automática, agitando o filtro sempre que o motor é desligado, eliminando o típico problema de fiabilidade do operador, que normalmente tem de se lembrar de ligar a limpeza do filtro. -

CESTO SEPARADOR PARA BALDE DE JACTO DE AREIA

AccessòriosACESSÓRIOS PARA ASPIRADORES INDUSTRIAIS IVISION

Trata-se de um crivo constituído por uma folha perfurada que permite, durante a aspiração, reter os resíduos gerados durante as operações de granalhagem e a sujidade em geral. Possui duas pegas cómodas que permitem retirar o recipiente e reposicioná-lo depois de o ter esvaziado. -

SEPARADOR DE LÍQUIDOS – APARAS

AccessòriosACESSÓRIOS PARA ASPIRADORES INDUSTRIAIS IVISION

Separador de aparas de malha metálica para lubrificação. Este acessório opcional permite separar perfeitamente os materiais sólidos aspirados do líquido, para facilitar o seu armazenamento e/ou eliminação. O separador de aparas retém o material sólido permitindo que o líquido se deposite no fundo do depósito de recolha. -

CLEAN 100

LINHA CLEANASPIRADORES INDUSTRIAIS PARA LIMPEZA GENÉRICA

Os aspiradores da linha CLEAN de 100 litros são equipados com alta capacidade de sucção e são utilizados para limpeza geral ou para coleta intensiva de poeira e aparas geradas por máquinas-ferramenta nos departamentos de produção das indústrias.A linha CLEAN é equipada com um cárter, ou seja, uma tampa para o motor e o soprador. Graças ao cárter, as partes mecânicas são protegidas contra poeira e sujidade e melhor preservadas ao longo do tempo. Além disso, o aspirador CLEAN 100 está equipado com um prático compartimento que facilita e agiliza ainda mais a atividade do operador de limpeza.O baixo nível de ruído, tamanho compacto, facilidade de uso e alta capacidade de sucção são as principais características dos aspiradores industriais CLEAN 100. -

CLEAN 160

LINHA CLEANASPIRADORES INDUSTRIAIS PARA LIMPEZAS GENÉRICAS

Os aspiradores industriais da linha Clean 160 são, sem dúvida, os mais potentes entre os aspiradores móveis de iVision e são usados para realizar trabalhos de limpeza importantes ou para realizar limpezas mais profundas de grandes máquinas de ferramentas com grandes acumulações de resíduos metálicos e líquidos. São usados para limpeza genéricas de empresas ou como integração em máquinas de ferramentas de vários tipos. Cada empresa metalúrgica produz - em grandes ou pequenas quantidades - aparas, pós e resíduos que devem ser aspirados de modo eficaz para manter limpas a oficina e as máquinas de ferramentas, mas sobretudo para salvaguardar a saúde dos operadores. Para este objetivo os aspiradores industriais da linha Clean 160 são a arma vencedora para manter limpa a empresa. Juntamente aos aspiradores da linha Clean 160, iVision projetou e produziu uma série dedicada de acessórios específicos para a indústria metalúrgica que fazem dos nossos aspiradores industriais máquinas indispensáveis em qualquer oficina. -

CLEAN 38

LINHA CLEANASPIRADORES INDUSTRIAIS PARA LIMPEZA GENÉRICA

Os aspiradores industriais da linha Clean de 38 litros são os mais compactos e fáceis de manusear de toda a gama iVision e foram concebidos para facilitar a limpeza de empresas e instalações de produção. Além da ampla gama de aspiradores industriais, a iVision projetou e patenteou muitos acessórios específicos para o mundo da aspiração industrial que podem ser associados à linha Clean. Entre os acessórios fornecidos com o aspirador CLEAN 38 encontra-se o kit de limpeza 50mm composto por escova com cabo de aço, mangueira flexível de 4 metros e lança plana. A linha CLEAN é equipada com um cárter, ou seja, uma tampa para o motor e o soprador. Graças ao cárter, as partes mecânicas são protegidas contra poeira e sujidade e melhor preservadas ao longo do tempo. Além disso, o aspirador CLEAN 38 está equipado com um prático compartimento que facilita e agiliza ainda mais a atividade do operador de limpeza. O baixo nível de ruído, tamanho compacto, facilidade de uso e alta capacidade de sucção são as principais características dos aspiradores industriais CLEAN 38. -

CLEAN Custom

LINHA CLEANASPIRADORES INDUSTRIAIS PARA LIMPEZAS GENÉRICAS

iVision está desde sempre atenta às exigências específicas de cada um dos seus clientes. A equipa de engenheiros presentes em IVISION GROUP desenvolve quotidianamente soluções personalizadas e inovadoras trabalhando ao lado do cliente para resolver problemas em centros de trabalho ou máquinas individuais. iVision, na verdade, desenvolveu vários sistemas de limpeza do filtro, um kit específico para a limpeza dos pavimentos ou também soluções para permitir a vários operadores de usar o mesmo aspirador simultaneamente. A nossa equipa de engenheiros poderá ajudar-lhe a identificar a solução mais adequada às exigências específicas de limpeza. -

KIT DE LIMPEZA Ø 50 mm

AccessòriosACESSÓRIOS PARA ASPIRADORES INDUSTRIAIS IVISION

O kit de limpeza é utilizável em todas as séries e é constituído por um tubo robusto e anti-abrasão que termina nas extremidades com acessórios especiais em aço zincado capazes de transportar, sem qualquer obstáculo, as aparas e o óleo da máquina-ferramenta para o depósito de recolha do vácuo. O tubo de aspiração vem alojado num suporte para facilitar o movimento do aspirador na oficina sem ser um obstáculo para o operador, permite evitar fugas de óleo durante as manobras do aspirador. -

PRÉ-FILTRO CICLÓNICO

AccessòriosACESSÓRIOS PARA ASPIRADORES INDUSTRIAIS IVISION

Fortemente recomendado sempre que possível, o pré-filtro é posicionado entre o vácuo e a máquina geradora de aparas, como o primeiro ponto de recolha do material recolhido. É especialmente utilizado para preservar a vida útil do filtro no interior da unidade de vácuo. Retém a maior parte do material recolhido e pode ter uma forma cónica ou cilíndrica, funcionando como um filtro mecânico. Através de uma entrada tangencial, o material recolhido é centrifugado para o seu interior até que a sua velocidade diminua gradualmente e o material caia gradualmente para o fundo da unidade de recolha devido à força da gravidade. Este processo assegura que apenas uma percentagem relativamente baixa do pó ou das aparas recolhidos consegue efetivamente chegar ao verdadeiro filtro posicionado na parte superior do aspirador. O pré-filtro ciclónico pode ser combinado com um: - Depósito de 160 L - Depósito de 500 L - Depósito de 1000 L O pré-filtro ciclónico torna-se quase obrigatório para os pós finos ou muito finos, que são muito susceptíveis de entupir rapidamente o filtro, comprometendo o bom funcionamento de todo o sistema, mas só é recomendado para as aparas grandes e pesadas. A principal vantagem do pré-filtro ciclónico é proteger o filtro do aspirador de entupir rapidamente, aumentando assim a sua vida útil antes da substituição e reduzindo significativamente a manutenção de todo o sistema. -

DUSTFREE 100

Dustfree LineASPIRADOR INDUSTRIAL PARA TRATAMENTO DE POEIRAS FINAS

Os aspiradores industriais da linha DUSTFREE foram desenvolvidos para o tratamento de poeiras finas. São colectores de poeiras capazes de aspirar poeiras finas e secas em contextos como o tratamento de superfícies a nível localizado e em suspensão. Podem ser ligados diretamente a equipamentos de preparação de superfícies ou utilizados autonomamente para aspiração localizada em bancadas de trabalho, sistemas de despoeiramento industrial e de purificação do ar, graças também ao braço telescópico articulado com o qual é possível captar micropoeiras em suspensão. Uma série de produtos que garante espaços limpos, livres de poeiras finas e tóxicas para o ambiente e para o operador. Os aspiradores DUSTFREE caracterizam-se pela elevada capacidade de aspiração, graças a potentes sopradores e ventiladores que geram caudais de ar até 2500 m3/h. Concebido para espaços apertados, o modelo 100 é o compromisso ideal entre compacidade e capacidade de sucção. O braço de aspiração tem um comprimento padrão de 3 metros e pode ser facilmente colocado no seu campo de ação graças a uma estrutura autoportante com molas reforçadas. Isto torna a sua posição durável ao longo do tempo. A campânula na extremidade pode ser posicionada com uma mão e permite a parcialização da aspiração. Um kit de recolha de poeiras com um saco interno permite esvaziar o contentor de forma rápida e segura. -

DUSTFREE 160

Dustfree LineASPIRADOR INDUSTRIAL PARA TRATAMENTO DE POEIRAS FINAS

Os aspiradores industriais da linha DUSTFREE foram desenvolvidos para o tratamento de poeiras finas. São colectores de poeiras capazes de aspirar poeiras finas e secas em contextos como o tratamento de superfícies a nível localizado e em suspensão. Podem ser ligados diretamente a equipamentos de preparação de superfícies ou utilizados autonomamente para aspiração localizada em bancadas de trabalho, sistemas de despoeiramento industrial e de purificação do ar, graças também ao braço telescópico articulado com o qual é possível captar micropoeiras em suspensão. Uma série de produtos que garante espaços limpos, livres de poeiras finas e tóxicas para o ambiente e para o operador. Os aspiradores DUSTFREE caracterizam-se por uma elevada capacidade de aspiração, graças a potentes sopradores e ventiladores que geram caudais de ar até 2500 m3/h. O modelo 160 é perfeito quando existe uma maior quantidade de pó no ar e é necessária uma elevada capacidade de aspiração. O braço de aspiração tem um comprimento padrão de 3 metros e pode ser facilmente colocado no seu campo de ação graças a uma estrutura autoportante com molas reforçadas. Isto torna a sua posição estável ao longo do tempo. A campânula na extremidade pode ser colocada com uma mão e permite parcializar a aspiração. Um kit de recolha de poeiras com um saco interno permite esvaziar o contentor de forma rápida e segura. -

DUSTFREE LONGOPAC

Dustfree LineASPIRADOR INDUSTRIAL PARA TRATAMENTO DE POEIRAS FINAS

Os aspiradores industriais da linha DUSTFREE foram desenvolvidos para o tratamento de poeiras finas. São colectores de poeiras capazes de aspirar poeiras finas e secas em contextos como o tratamento de superfícies a nível localizado e em suspensão. Podem ser ligados diretamente a equipamentos de preparação de superfícies ou utilizados autonomamente para aspiração localizada em bancadas de trabalho, sistemas de despoeiramento industrial e de purificação do ar, graças também ao braço telescópico articulado com o qual é possível captar micropoeiras em suspensão. Uma série de produtos que garante espaços limpos, livres de poeiras finas e tóxicas para o ambiente e para o operador. Os aspiradores DUSTFREE caracterizam-se por uma elevada capacidade de aspiração, graças a potentes sopradores e ventiladores que geram caudais de ar até 2500 m3/h. A entrada tangencial com ciclone integrado e o sistema automático de limpeza de cartuchos com compressor a bordo tornam este modelo extremamente fiável e o resultado de aspiração excelente, essencial para o tratamento de superfícies. O sistema de recolha de poeiras LONGOPAC - ENDLESS BAG evita qualquer contacto do operador com as poeiras recolhidas. Além de proteger o filtro, através de avisos visuais e acústicos, um sensor de enchimento garante que os sacos do mesmo tamanho sejam sempre libertados. -

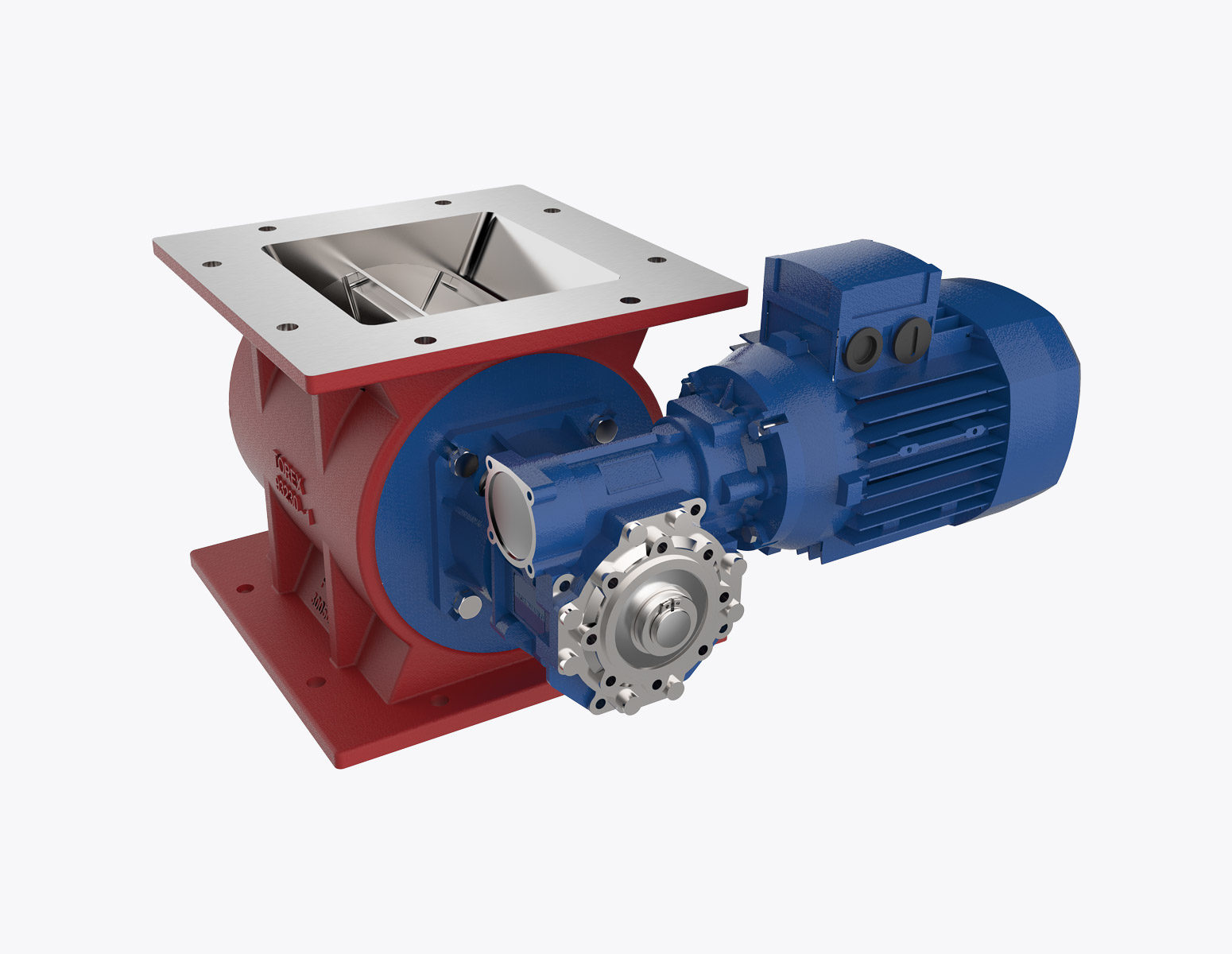

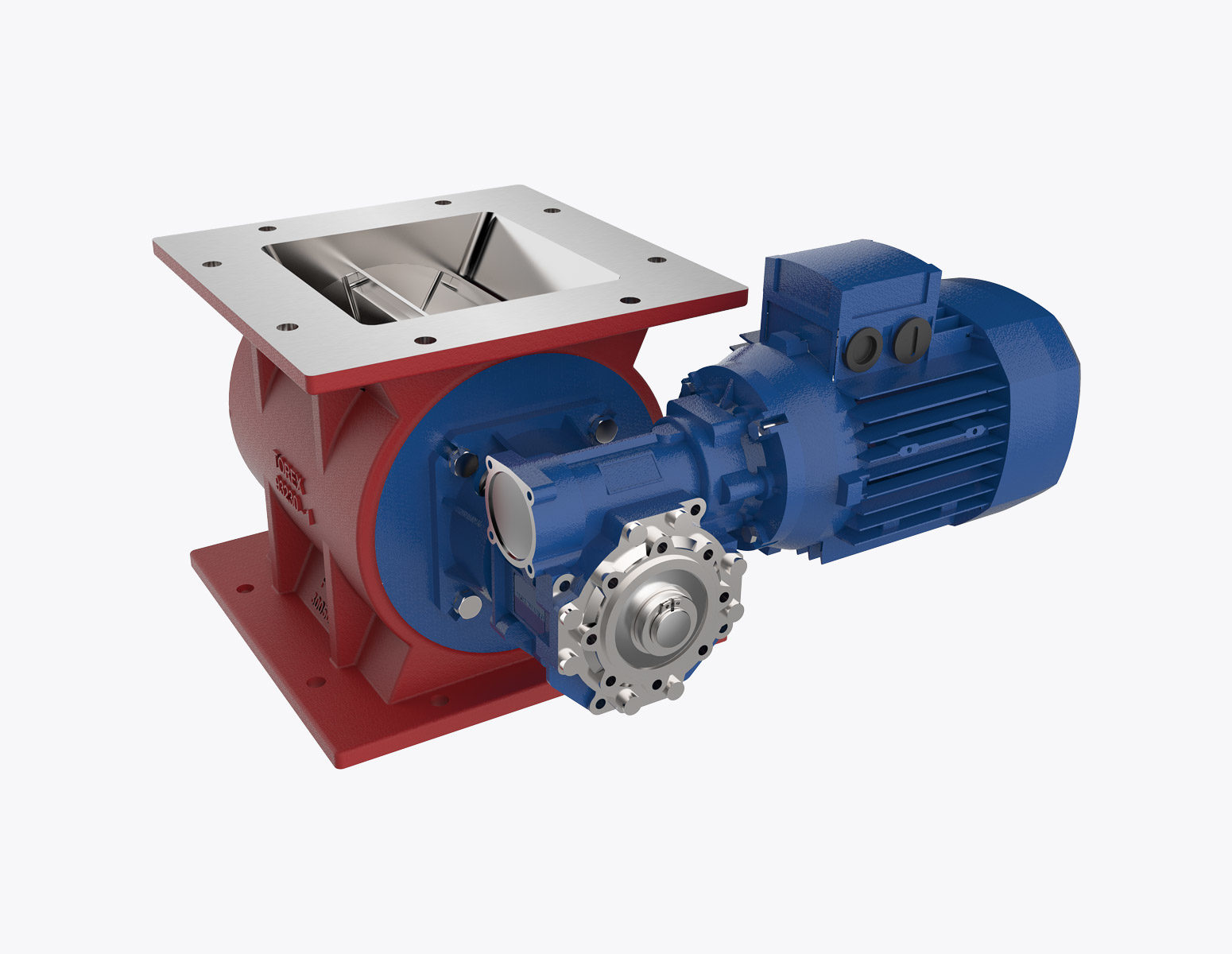

EMPTYING ROTARY VALVE KIT FOR CONTINUOUS WORK

AccessòriosHI-TECH VACUUM

For those that need a continuous work cycle in construction environments and need to empty without interrupting work due to turning off the vacuum to empty the collection container, the iVision rotary valve kit is an interesting solution. -

EMULSIO 100

LINHA EMULSIOASPIRADORES INDUSTRIAIS PARA COLETA E SEPARAÇÃO DE APARAS E ÓLEO

Os aspiradores industriais da linha EMULSIO foram desenvolvidos para o setor de mecânica industrial onde a necessidade específica consiste na sucção de líquidos misturados com aparas e no reaproveitamento de líquidos emulsificados gerados durante o processamento de fresadoras, tornos e centros de usinagem numérica ao controlo. A linha EMULSIO 100 inclui quatro configurações diferentes para diferentes necessidades de uso. -

EMULSIO 100 1~

LINHA EMULSIOASPIRADORES INDUSTRIAIS PARA COLETA E SEPARAÇÃO DE APARAS E ÓLEO

Os aspiradores industriais da linha EMULSIO foram desenvolvidos para o setor de mecânica industrial onde a necessidade específica consiste na sucção de líquidos misturados com aparas e no reaproveitamento de líquidos emulsificados gerados durante o processamento de fresadoras, tornos e centros de usinagem numérica ao controlo. A linha EMULSIO 100 1~ inclui quatro configurações diferentes para diferentes necessidades de uso. -

EXTRUSION 100

LINHA EXTRUSIONASPIRADORES INDUSTRIAIS PARA APARAS DE ALUMÍNIO E PVC

Os aspiradores 100 da linha Extrusion da gama iVision são normalmente acoplados a grandes máquinas de corte de cabeça individual ou pequenas máquinas de corte de cabeça dupla. Muito versáteis, encontram a sua aplicação ideal em produtores de portas e janelas de PVC ou alumínio onde as características das potentes ventoinhas centrífugas podem ser usufruídas ao máximo. A realização com o uso de materiais robustos, a grande atenção prestada à construção e ao design permitiram a estes aspiradores de se afirmar no mundo da extrusão e da carpintaria onde iVision é reconhecida como sinónimo de qualidade, fiabilidade, inovação e eficiência. -

EXTRUSION 1000

LINHA EXTRUSIONASPIRADOR INDUSTRIAL PARA APARAS DE ALUMÍNIO E PVC

A EXTRUSION 1000 litros é ideal para utilização em combinação com serras de cabeça dupla ou centros de corte automáticos com elevada produção de aparas e poeiras:- um pré-filtro de ciclone que capta mais de 90% do material extraído antes de chegar ao filtro principal

- um contentor de 1000 litros com abertura pneumática e sistema prático de descarga basculante