-

OIL MIST 1000

Oil MistINDUSTRIAL VACUUM CLEANERS FOR OIL MIST

Designed for the suction and purification of air from oily mists and fumes, the OIL MIST 1000 model is ideal for connection to small and medium-sized processing machines. This model is intended for connection to work stations, lathes and machine tools with an internal volume > 3 m3 and to lathing machines with oil injectors = 20 mm. The main cartridge filter, made of glass microfibre together with the microfibre prefilter inside a metal cell, guarantees filtration with an efficiency of 99%. -

OIL MIST 1500

Oil MistINDUSTRIAL VACUUM CLEANERS FOR OIL MIST

Designed for the suction and purification of air from oily mists and fumes, the OIL MIST 1500 model is ideal for connection with machines for processing most complex components. This model is intended for connection with work stations, lathes and machine tools with an internal volume > 6 m3 and with lathing machines with oil injectors= 30 mm. The main glass microfibre cartridge filter, together with the microfibre pre-filter inside a metal cell, guarantees filtration with an efficiency of 99%. -

OIL MIST 2000

Oil MistINDUSTRIAL VACUUM CLEANERS FOR OIL MIST

Designed for the suction and purification of air from oily mists and fumes, the OIL MIST 2000 model is ideal for connection to machines for the processing of most complex components. This model is intended for connection to work stations, lathes and machine tools with an internal volume > 12 m3. The main glass microfibre cartridge filter, together with the microfibre prefilter inside a metal cell, guarantee filtration with an efficiency of 99%. -

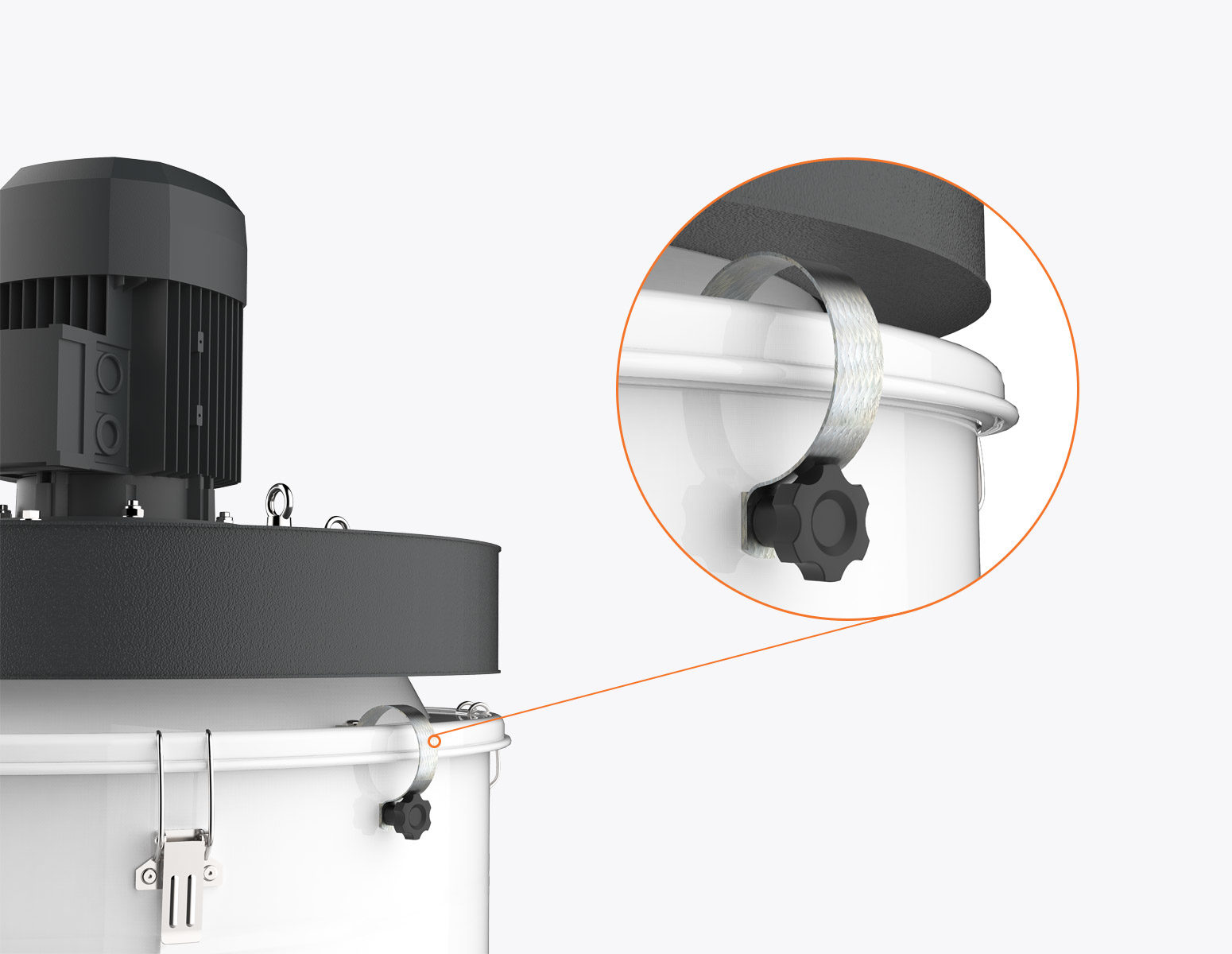

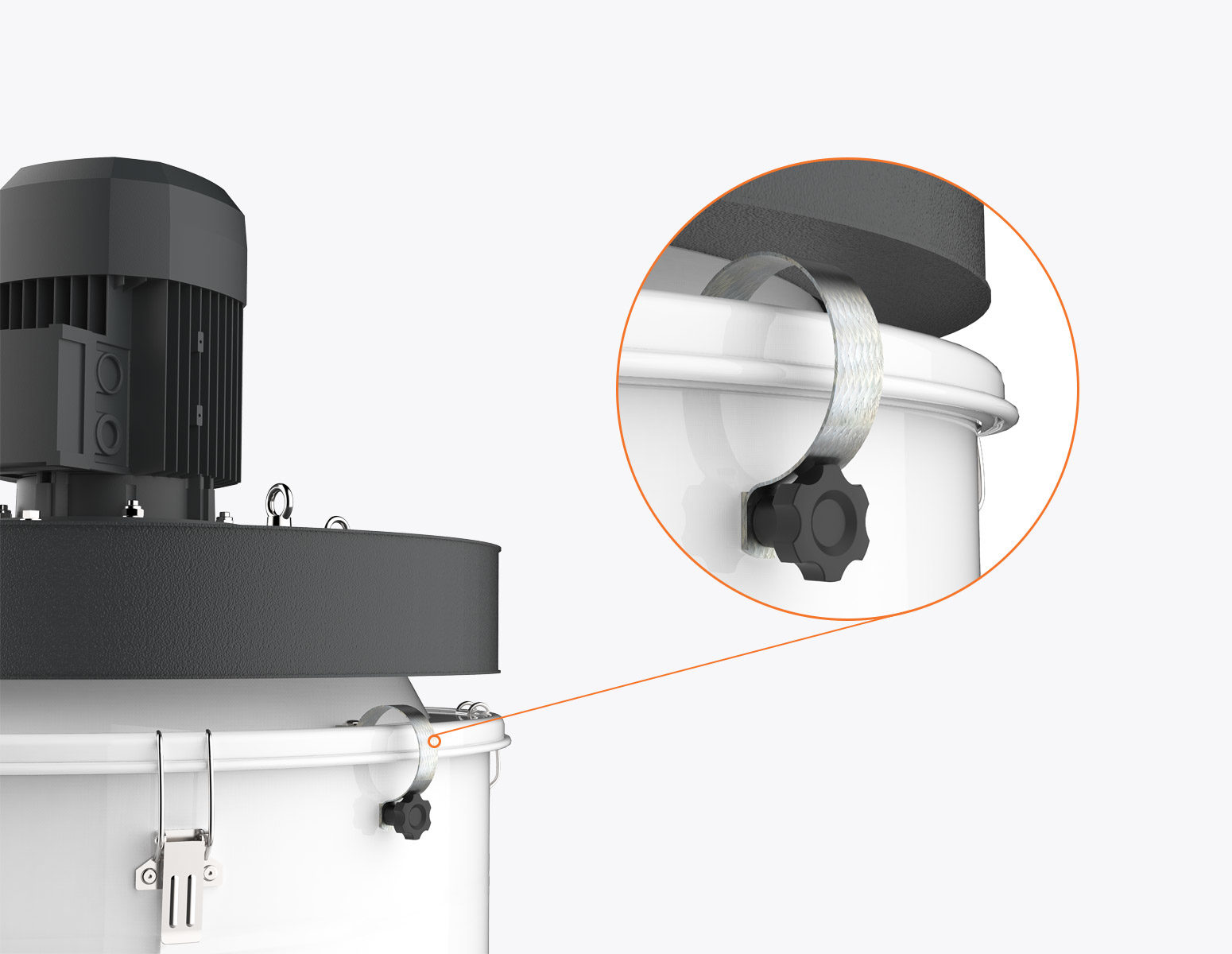

ADDITIONAL DUMPSTER

AccessoriesHI-TECH VACUUM

In the case that the vacuum cleaner standard capacity 42 Gal is not enough, iVision offers its customers additional high-capacity chip containers. Ivision has developed 2 types of dumpsters: A) 1000 Lt dumpster with automatic opening B) 500 Lt dumpster with manual opening The dumpsters are equipped with a visual filling indicator that shows the operator when it is time to empty the container. -

AERIAL ARM

AccessoriesHI-TECH VACUUM

The aerial arm is highly recommended for every CNC router. The use of this system reduces the risk of accidents due to obstruction of the tube on the sides of the machine. -

ANTI-FIRE KIT

AccessoriesHI-TECH VACUUM

This accessory is a device that automatically intervenes in the case that there is a consistent increase of the temperature inside of the collection tank, emptying a mix of air and water inside the tank through a spray nozzle. In the case where the system is not automatically activated, it's possible to activate it manually using the appropriate button. -

ANTISTATIC KIT

AccessoriesHI-TECH VACUUM

To be applied to all models of industrial vacuums in production. This kit allows you to unload electrostatic charges accumulated during the collection phase, avoiding transferring them to other machinery or operators. It’s particularly recommended during the working of aluminum, considering the chips of this material can create a potentially explosive atmosphere inside of the tank. -

AUTOMATIC CLEANING WITH SHAKING

AccessoriesHI-TECH VACUUM

Filter cleaning with a pneumatic piston requires being connected to an air adapter from 6-8 bar and via a pressure regulator that can vary the intensity of the sliding of the piston. • To effectively clean the filters mounted inside the vacuum, the vertical piston filter cleaning system was developed. Through a manual selector (semiautomatic solution) or by a timer (automatic version) a pneumatic piston acts from the bottom of the filter, shaking it intensely in a way that ensures that the chips or the dust transferred to the outside of the filter fall into the collection tank, permitting in this way the continued optimal functioning of the filter. • Vertical piston cleaning of the filter is recommended for any type of application, as it significantly improves the cleaning of the filter compared to the vibrating motor standard version. • Vertical piston cleaning of the filter, especially in its automatic version, becomes mandatory in the suctioning of fine dust that can clog the filter rapidly. In the case of large and heavy chips, this system is not mandatory, but for light or volatile material, yes! • The principal advantage of this system comes from the greater efficiency in the incisiveness of the shaking of the filter with a piston. Another advantage is the use of this system in its automatic version, shaking the filter every time that the motor is turned off, eliminating the typical problem of the reliability of the operator, who usually has to remember to turn on the cleaning of the filter. -

CHIP SEPARATOR TANK FOR SANDBLASTING CONTAINER

AccessoriesHI-TECH VACUUM

This is a sieve made of a perforated sheet that allows, during suction, to retain the residue generated during blasting oprations and in general dirt. It has two comfortable handles the permit the removal of the container and the repositioning after having emptying the container. -

CHIPS SEPARATOR

AccessoriesHI-TECH VACUUM

Metallic mesh chips separator from lubrication. This optional accessory allows you to perfectly separate aspirated solid materials from liquid, to facilitate their storage and/or disposal. The chip separator holds the solid material allowing the liquid to deposit to the bottom of the collection tank. -

-

-

CLEAN 38

一般清洗用于一般清洁的工业吸尘器

38 升 Clean 系列的工业真空吸尘器是整个 iVision 系列中最紧凑、最易于操作的产品,旨在优化公司和生产车间的清洁。 除了种类繁多的工业真空吸尘器外,iVision 还为工业吸尘领域设计了许多可与 Clean 系列相关联的特定附件并取得专利。CLEAN 38 真空吸尘器随附 50 毫米清洁套件,包括带钢柄的刷子、4 米长的柔性软管和扁平喷枪。 CLEAN 系列配备保护电机和鼓风机的护罩。该护罩可以使得机械部件免受灰尘和污垢的入侵,可以确保更长寿的使用寿命。此外,CLEAN 38 真空吸尘器配备实用的储物格,进一步方便和加快清洁操作员的活动。 CLEAN 38 工业真空吸尘器的主要特点是噪音低、尺寸紧凑、易于使用和吸力大。 -

CLEAN CUSTOM

一般清洗常规清洁用工业真空吸尘器

iVision始终关注每一位客户的具体需求。 iVision集团的工程师团队开发创新和定制的解决方案,长期与客户密切合作,帮助客户解决加工中心和单机的问题。 常规清洁系列的iV定制工业吸尘器可根据客户的具体需要定制。iVision已经开发了许多过滤器清洁系统,一个专门用于清洁地板的套件,甚至是允许多个操作员同时使用同一台工业吸尘器的解决方案。 我们的工程师团队将能够帮助您找到较适合您特定清洁需求的解决方案。 -

CLEANING KIT Ø 50 mm

AccessoriesACCESSORIES KLEANING KIT Ø 50 mm

The cleaning kit is usable on all of the series and consists of a robust, anti-abrasion tube that ends at the extremities with special zinc-plated steel accessories capable of transporting, without any obstacle, chippings and oil from the machine tool to the vacuum collection tank. The suction tube comes housed inside a support in order to facilitate the movement of the vacuum in the workshop without being an obstable for the operator, it allows the avoidance of leakage of oil during the maneuvers of the vacuum. -

CYCLONIC PREFILTER

AccessoriesHI-TECH VACUUM

Strongly recommended whenever possible, the pre-filter is positioned between the vacuum and the chip-generating machine, as the first point of collection of the collected material. It is specially used to preserve the life of the filter inside the vacuum unit. It retains most of the collected material and can have a cone or cylindric shape and serves as a mechanical filter. Through a tangential entry the collected material is centrifuged into its interior until its speed gradually decreases and the material gradually falls to the bottom of the collecting unit due to the force of gravity. Such a process ensures that only a relatively low percentage of collected dust or chips manages to actually reach the real filter positioned in the upper part of the vacuum cleaner. The cyclonic pre-filter can be combined with a: • 160 L tank • 500 L tank • 1000 L tank The cyclonic pre-filter becomes almost mandatory for fine or very fine powders, which are very likely to clog the filter quickly, compromising the smooth operation of the entire system, but are only recommended for large, heavy chips. The main advantage of the cyclonic pre-filter is to protect the filter of the vacuum cleaner from quickly clogging, thus extending its life before replacement and significantly reducing the maintenance of the entire system. -

DUSTFREE 100

Dustfree LineINDUSTRIAL VACUUM CLEANER FOR TREATMENT OF FINE DUST

The industrial vacuum cleaners of the DUSTFREE line have been developed for the treatment of fine dust. They are dust collectors capable of vacuuming up fine and dry dust in contexts such as surface treatment at localised and suspended levels. They can be connected directly to surface preparation equipment or used stand-alone for localised suction on workbenches, industrial dedusting and air purification systems, thanks also to the articulated telescopic arm with which suspended micro-dust can be captured. A series of products which guarantees clean spaces, free of fine dust and toxic for the environment and the operator.DUSTFREE vacuum cleaners are characterised by high suction capacity, thanks to powerful blowers and fans that generate air flow rates of up to 2500 m3/h. Designed for tight spaces, the model 100 is the optimal compromise between compactness and suction capacity. The suction arm has a standard length of 3 metres and can be easily placed within its field of action thanks to a self-supporting structure with reinforced springs. This makes its position durable over time. The hood at the end can be positioned with one hand and allows the suction to be partialised. A dust collection kit with an internal bag allows the container to be emptied quickly and safely. -

DUSTFREE 160

Dustfree LineINDUSTRIAL VACUUM CLEANER FOR TREATMENT OF FINE DUST

The industrial vacuum cleaners of the DUSTFREE line have been developed for the treatment of fine dust. They are dust collectors capable of vacuuming up fine and dry dust in contexts such as surface treatment at localised and suspended levels. They can be connected directly to surface preparation equipment or used stand-alone for localised suction on workbenches, industrial dedusting and air purification systems, thanks also to the articulated telescopic arm with which suspended micro-dust can be captured. A series of products which guarantees clean spaces, free of fine dust and toxic for the environment and the operator. DUSTFREE vacuum cleaners are characterised by high suction capacity, thanks to powerful blowers and fans that generate air flow rates of up to 2500 m3/h.The model 160 is perfect where there is a greater amount of dust in the air and a high suction capacity is required. The suction arm has a standard length of 3 metres and can be easily placed within its field of action thanks to a self-supporting structure with reinforced springs. This makes its position stable over time. The hood at the end can be placed with one hand and allows the suction to be partialised. A dust collection kit with an internal bag allows the container to be emptied quickly and safely. -

DUSTFREE LONGOPAC

Dustfree LineINDUSTRIAL VACUUM CLEANER FOR TREATMENT OF FINE DUST

The industrial vacuum cleaners of the DUSTFREE line have been developed for the treatment of fine dust. They are dust collectors capable of vacuuming up fine and dry dust in contexts such as surface treatment at localised and suspended levels. They can be connected directly to surface preparation equipment or used stand-alone for localised suction on workbenches, industrial dedusting and air purification systems, thanks also to the articulated telescopic arm with which suspended micro-dust can be captured. A series of products which guarantees clean spaces, free of fine dust and toxic for the environment and the operator.DUSTFREE vacuum cleaners are characterised by high suction capacity, thanks to powerful blowers and fans that generate air flow rates of up to 2500 m3/h. The tangential inlet with integrated cyclone and the automatic cartridge cleaning system with on-board compressor make this model extremely reliable and the suction result excellent, essential for surface treatment.The LONGOPAC – ENDLESS BAG dust collection system avoids any contact by the operator with the collected dust. Further protecting the filter, through visual and acoustic warnings, a fill sensor ensures that bags of the same size are always released. -

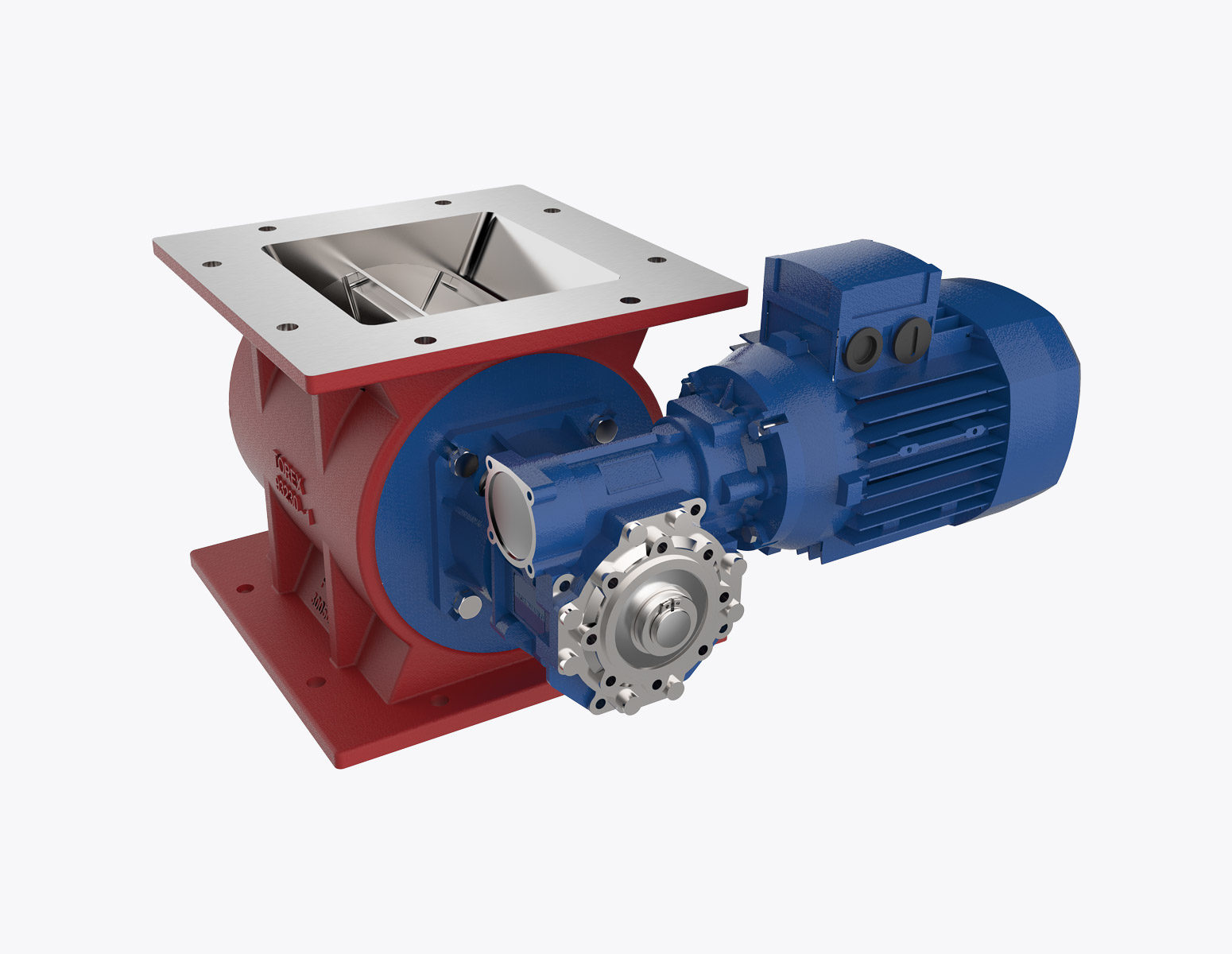

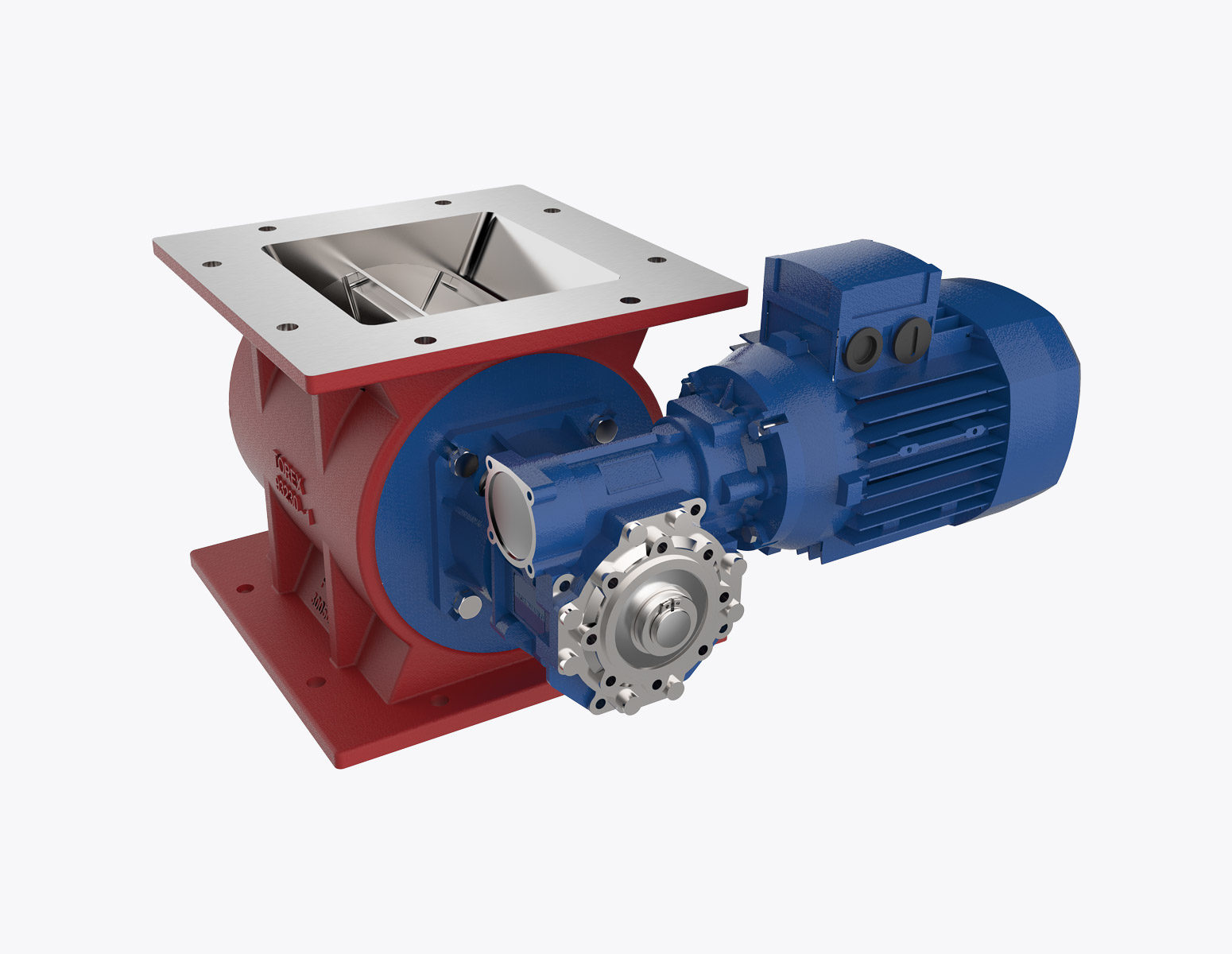

EMPTYING ROTARY VALVE KIT FOR CONTINUOUS WORK

AccessoriesHI-TECH VACUUM

For those that need a continuous work cycle in construction environments and need to empty without interrupting work due to turning off the vacuum to empty the collection container, the iVision rotary valve kit is an interesting solution. -

EMULSIO 100

机械生产用于收集并分离刨花和油的工业真空吸尘器

EMULSIO 系列的真空吸尘器是为工业机械领域专门开设计的,可以满足该领域的特定需求,如抽吸与刨花混合的液体,以及重新回收和利用数控铣床、车床和加工中心在加工过程中产生的乳化液体。 EMULSIO 100 系列包括四种不同的配置,可满足不同的使用需求。 -

EMULSIO 100 1~

机械生产用于收集并分离刨花和油的工业真空吸尘器

EMULSIO 系列的真空吸尘器是为工业机械领域专门开设计的,可以满足该领域的特定需求,如抽吸与刨花混合的液体,以及重新回收和利用数控铣床、车床和加工中心在加工过程中产生的乳化液体。 EMULSIO 100 1~ 系列包括四种不同的配置,可满足不同的使用需求。 -

EXTRUSION 100

除尘设备铝片和PVC芯片用工业吸尘器

100工业除尘器一般情况下与大单头锯或小双头锯一起使用。 这台多功能的工业吸尘器是PVC和铝材制造商中的理想应用选择,大风量的离心风机是这个系列的特点,可以有效地利用。 坚固的材料使用,对设备的精心设计,使iVision工业吸尘器被行业内认可,是质量、可靠性、创新和效率的一种标准。 -

EXTRUSION 1000

除尘设备INDUSTRIAL VACUUM CLEANERS FOR METAL & PVC CHIPS

EXTRUSION 1000 litres is ideal for use in combination with doublehead saws or automatic cutting centres with high chip and dust production.This model features:- a cyclone pre-filter that captures more than 90% of the extracted material before it reaches the main filter

- a 1000-litre container with pneumatic opening and practical tipping unloading system

-

EXTRUSION 160

除尘设备金属真空和PVC芯片用工业吸尘器

160除尘器是iVision除尘器中畅销的机型。 优秀的除尘设备被用于吸除双头锯或自动切割中心与高产量的 屑和粉尘。 由于我们针对工业真空多年的定制案例,iVision能够通过使用坚固的材料、良好的维护和对设计的关注,来满足客户对除尘器所有所有的吸力的需求。 160工业除尘器适用在各个领域,在性能、效率和创新方面也得到了各行业客户的认可 -

EXTRUSION 320

除尘设备INDUSTRIAL VACUUM CLEANERS FOR METAL & PVC CHIPS

The 320 vacuum cleaners of the Extrusion line are designed specifically for industrial purposes, this model is equipped with powerful motors and an advanced filtering system.Its vacuum characteristics and air flow rate make it ideal for the suction of chips or dust.The use of a cyclonic pre-filter captures more than 90% of the suctioned material before it reaches the main filter, thus preventing it from clogging and considerably extending its life. -

EXTRUSION 38

除尘设备金属和PVC专用工业吸尘器

38工业除尘器是iVision系列中较小的工业除尘器。 通常与小型打磨、切削机床配套使用,或者通常用于产生废屑和灰尘较少的所有工作领域,因为它们收集轻材料的效果是非常理想的,如PVC、铝和其他轻合金。 38的实际尺寸可让工人能够在狭小的地方进行操作,既敏捷又实用,充分利用了工业除尘器出色的功能和性能。 由于配备了三相电机,不需要过多维护就可以保证长时间安全工作。 -

EXTRUSION CUSTOM

除尘设备INDUSTRIAL VACUUM CLEANER FOR METAL AND PVC CHIPS

The CUSTOM vacuum cleaners of the Extrusion line are among the most advanced models in the iVision range and are usually used together with automatic cutting centres.This vacuum cleaner is equipped with a high flow rate fan (pressurised system) that extracts large amounts of chips, which are continuously discharged.This occurs thanks to the continuous discharging system into big bags through a rotary valve.An innovative system of filling sensors is able to provide the operator with an alarm when the bigbag is about to fill, so that the operator can replace the bigbag in time and prevent the machine from stopping. -

FILTER

AccessoriesHI-TECH VACUUM

The classification filters for vacuum cleaner and powders emissions into the environment, is assigned by the type of powders and the degree of danger to health. For its suction devices such classification is regulated by IEC 60335-2-69 worldwide. This classification provides several categories of powders, such as: • Category of powders L (low/moderate): fall into that category powders with MPC values (maximum permitted concentration in the work place) > 1 mg / m³Are retained at least 99% of particles aspirated.The disposal of the collected material must be made trying to raise a few powders. • Category of powders M (medium): fall into that category powders with MPC values (maximum permitted concentration in the work place) > 0.1 mg / m³ and wood powdersAre retained at least 99.9% of particles aspirated.The disposal of the collected material must be made trying to raise a few powders. • Category of powders H (high): fall into that category powders with MPC values (maximum permitted concentration in the work place) < 0.1 mg / m³, with carcinogenic and pathogenic powdersAre held at least 99.995% of particles aspirated.The disposal of the collected material must be done without raising powders. On each iVision vacuum cleaner is applied a label indicating the hazard class of the dust in the environment allowed. -

FLAT TABLE 100

CNC机床数控机床配套的工业吸尘器

iVision FLAT TABLE 100工业吸尘器的FLAT TABLE LINE是较畅销的型号。 虽然体积小巧,但iV2吸尘器有一个100升的集尘箱,即使在狭小的空间也很容易使用。这意味着它们适合与三轴铣床匹配,三轴铣床产生大量废料和材料进行真空处理,以保证完美的较终产品。 -

FLAT TABLE 160

CNC机床数控机床配套的工业吸尘器

FLAT TABLE 160 工业吸尘器是iVision系列中性能较好的型号,非常适合在大型数控机床中配套收集粉尘。 由于强大的侧通道风机和大型粉尘收集器(160lt),FLAT TABLE 160系列工业吸尘器非常适合大型加工中心的维护和清洁,这些加工中心产生大量的废料、刨花和灰尘。 三轴数控机床上刀具产生的废料需要尽可能高效地进行工业排屑,以确保机床准确、正确地工作。 我们专门为这一领域制造的配件,例如创新的吊臂,使iVision能够为每种应用提供合适的产品。 iVision工业吸尘器的特点是采用高科技部件,结合精心的维护和设计。 -

FLAT TABLE 320

CNC机床INDUSTRIAL VACUUM CLEANER FOR CHIP ON CNC ROUTER.

The FLAT TABLE 320 model is used in the world of machining with 3-axis CNC machines with high dust/chip production. Designed specifically for industrial purposes, this model is equipped with powerful motors and advanced performing filtration system.Its vacuum and airflow characteristics make it ideal for heavy dust extraction.The use of a pre-filter-cyclone enables it to capture more than 90% of the sucked material before it reaches the main filter, thus preventing clogging and greatly extending its service life. -

FLAT TABLE 38

CNC机床数控机床配套的工业吸尘器

FLAT TABLE的38吸尘器是iVision系列中较紧凑实用的型号。 这些工业吸尘器都侧通道风机,用于收集小型CNC小型机床产生的粉尘。三轴铣床产生的废物需要非常高效的工业提取粉尘,以保证绝对的清洁度。 紧凑的尺寸允许操作员在密闭空间中灵活地移动,从而充分利用了侧通道风机的卓越性能。 -

FREQUENCY INVERTER

AccessoriesHI-TECH VACUUM

Compact technology, powerful and built-to-last this characterizes the frequency inverter that regulates and manages the performance of iVision vacuums. The inverter operates the normal work of the turbines or intervenes instantaneously in all of the possible emergencies that may occur by increasing or decreasing the RPM of the engines in order to ensure the same performance for the system even in the case that a machine that the vacuum is attached to stops working. -

GATE CLOSURE

AccessoriesHI-TECH VACUUM

The gate valves that enable the closure of multiple vents allow the operator to choose to work with one, two or more hoses simultaneously. These gates can be operated manually by operators, handled automatically by machines, or remotely via foot pedal. -

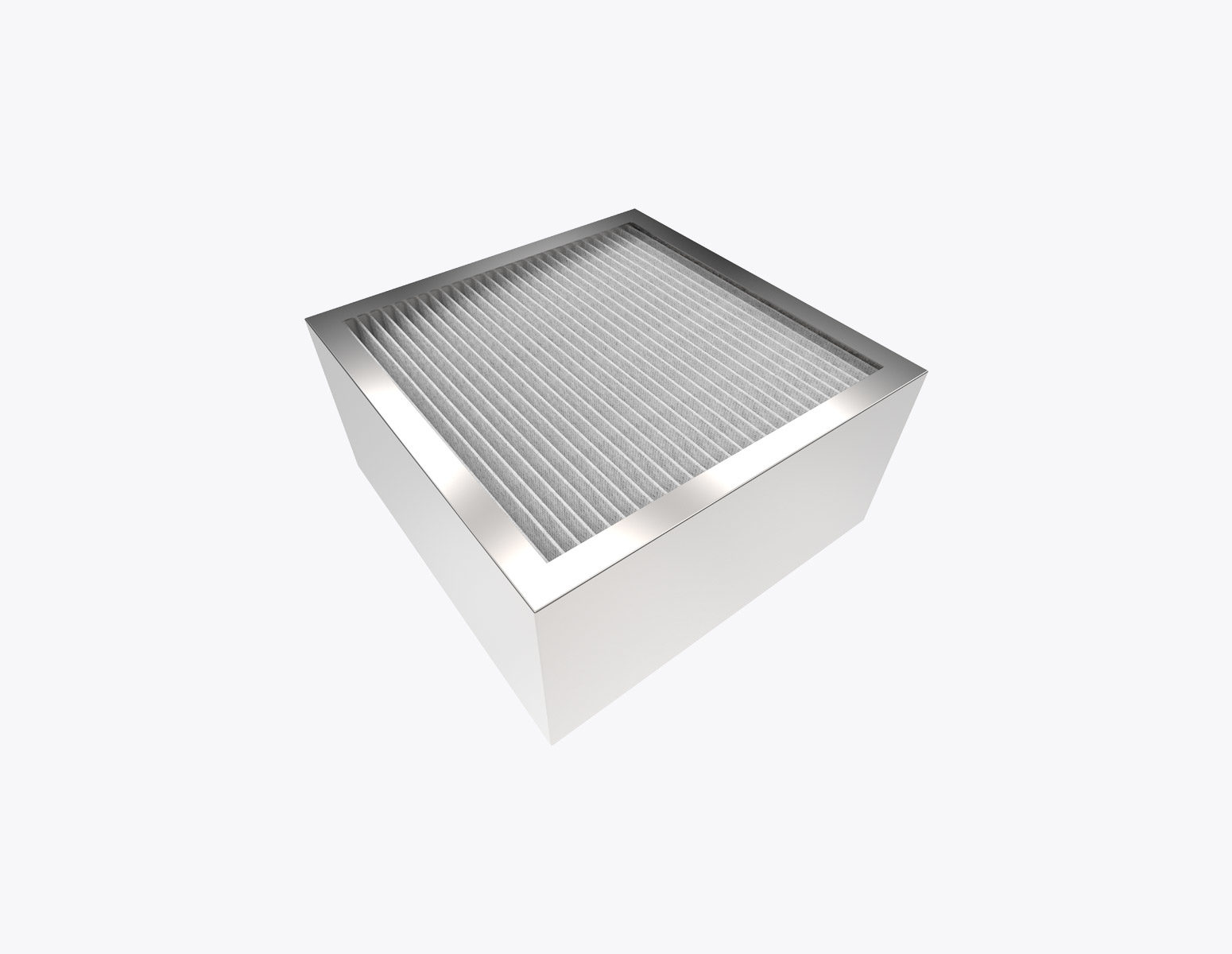

HEPA FILTER

AccessoriesHI-TECH VACUUM

HEPA is the acronym used for the definition “High Efficiency Particulate Air”. It ‘a kind of filter for vacuum cleaner with a particular system of filtering with high efficiency for fluid, liquid or gas. It has the ability to trap a very high amount of particles of very small size, ability that other filters for vacuum cleaners do not have. Indeed, there are different categories of filters (L / M / H), and different categories of HEPA filters, that has made according to the material more efficient to inhale. The HEPA filter is composed from microfiber filter sheets (generally borosilicate) assembled in multiple layers, and separated by aluminum septa. The microfiber filter sheets have the task to block the polluting solid particles (or particulate). The solid particles are very small and can be harmful to health or may affect the quality of the final product to be obtained. HEPA filters are part of the category of the “absolute filters”, justified by the fact that these filters have a high efficiency of filterign. In particular, HEPA filters introduce an efficiency of filtering between 85% (H10) and 99.995% (H14). The filtration efficiency of particles of 0.3 µm, is regulated by the UNI EN 1822. -

LIFT KIT

AccessoriesHI-TECH VACUUM

The lifting device is used for emptying the 100 Lt (iV2 model) or the 160 Lt (iV3 model) chip container with the use of a forklift. The operators do not have to make any effort for the emptying process. At the sides of the collecting containers there are two hooks for the lifting kit to be connected to, which in turn is lifted from the truck by a chain. -

OIL MIST 600

Oil MistINDUSTRIAL VACUUM CLEANERS FOR OIL MIST

Designed for the suction and purification of air from oily mists and fumes, the OIL MIST 600 model is ideal for connecting to machines for the processing of small components. This model is intended for use with work stations, lathes and machine tools with an internal volume > 1 m3 and with lathing machines with oil injectors < 20 mm. The main cartridge filter, made of glass microfibre together with the microfibre prefilter inside a metal cell, guarantees filtration with an efficiency of 99%. -

PCB 100

印刷电路板 (PCB)玻璃纤维和铝用工业吸尘器

PCB line的100工业吸尘器专为工业领域而设计,并配备了强大的侧通道风机和尖端过滤系统。 100的负压和气流特性非常适合于收集由2到6个主轴的钻床和铣床产生的碎屑和重尘。 这一系列创新的工业真空吸尘器型号在欧洲、美国和亚洲国家的印刷电路板制造业中获得了巨大成功。 得益于PCB 100系列的新技术,钻床或铣床产生的废料在加工过程中得到有效收集,以保证最终产品的完美无瑕。 除了配置侧通道风机,iVision还为 PCB line设计了一系列特定配件与100系列配套使用,使我们的设备成为每个PCB生产车间的理想和不可或缺的解决方案。 -

PCB 160

印刷电路板 (PCB)玻璃纤维和铝用工业吸尘器

PCB line的160工业吸尘器移动灵活,用于收集CNC钻床和大型铣床(6-8轴)的刨花和灰尘。 这一系列工业吸尘器可以在他们的基础结构上进行定制,也可装配变频器,作为真正的中央除尘系统运作。 在欧洲和美国,iVision的160工业吸尘器的都因其性能、多功能性和定制化而备受青睐,它们保证了加工过程中没有碎屑和灰尘,因此是一款无懈可击的除尘产品。 iVision为印刷电路行业设计、生产并配置了一系列定制功能,如触摸屏和HMI(人机交互界面),这是大型PCB制造工厂不可或缺的理想选择。 -

PCB 320

印刷电路板 (PCB)玻璃纤维和铝用工业吸尘器

PCB 320 line的iVision工业吸尘器由一个旋风预滤器、一个带侧通道风机的中央单元、一个集成过滤器、一个带有变频器的电气面板以及带有彩色触摸屏的PLC管理控制中的所有必要组件组成。该系统还配备了一个强大的消音器,以确保完全符合国际标准。 iV定制的工业吸尘器是市场上技术较先进的集中式系统之一,不能与任何传统上已知的系统相比。 iVision员工的长期经验,以及渴望满足客户的需求,促成了高科技产品和定制化解决方案的开发。iV定制 PCB line配置变频器可以使工业吸尘器可以同时配套多台CNC机器。 过滤器污染检测装置(可选)能够精确测量工业吸尘器过滤器的效率,大大减少维护时间,保证稳定的性能和持久的集中抽尘。 -

PCB 38

印刷电路板 (PCB)玻璃纤维和铝用工业吸尘器

PCB line的38工业吸尘器是iVision系列中较小的工业除尘器,通常用于在一个或两个主轴的小型机器中收集粉尘和灰尘。 38的实际尺寸可让工人能够在狭小的地方进行操作,既敏捷又实用,充分利用了工业除尘器出色的功能和性能。 效率、耐用和免维护,以及意大利部件的设计和使用,是iVision工业吸尘器的基本特点。 除了配备三相电机,iVision还为PCB行业设计了一系列特定配件,可以与38系列相配套,使我们的设备成为每个PCB生产车间的理想和不可或缺的解决方案。 -

PCB CUSTOM

印刷电路板 (PCB)INDUSTRIAL VACUUM CLEANER FOR FIBERGLASS AND ALUMINIUM

The vacuum cleaners of the PCB line are dedicated to machines for the production of printed circuits such as drilling, milling or contouring machines, which require accurate and efficient extraction of chips/dust.The CUSTOM model features a continuous discharging system with rotary valve that discharges the material directly into bigbags.The detection sensors and the sound and visual alarm system are designed to provide the operator with the maximum support.The separate 4-independent cartridge cleaning system allows maximum efficiency at all times. iVision© HMI system allows full control of the system and its efficiency, easily and intuitively. -

REMOTE START & STOP

AccessoriesHI-TECH VACUUM

The kit allows the automatic switching on and off of the vacuum cleaner simultaneously with the machine tool when they are connected. This can occur in three different ways: a) The vacuum gets switched on by contact without electricity "potential free contact". b) The vacuum gets switched on with a 24V contact. c) The vacuum gets switched on with a 230V contact. -

-

SAND CUSTOM

喷砂处理ASPIRATORI INDUSTRIALI PER SABBIATURA

Gli aspiratori della linea SAND sono creati per soddisfare le specifiche richieste dei clienti. iVision ha sviluppato sistemi di aspirazione centralizzati con il sistema di scarico continuo con rotovalvola che funziona in modo continuo e scarica il materiale direttamente in contenitori alloggiati all’interno del box (un big bag, un contenitore o la vs sabbiatrice). Il Sistema è costruito in carpenteria pesante appositamente studiata e collaudata per impieghi intensivi e speciali.Questo particolare sistema permette di alloggiare la vostra sabbiatrice al di sotto della rotovalvola, così che il materiale vi venga scaricato direttamente. È previsto un sistema di prefiltro ciclonico per depolverazione graniglia e scarico parte pesante in big bag/contenitore/sabbiatrice.Un ulteriore setaccio per la separazione della graniglia è previsto per evitare che particelle troppo grosse arrivino in sabbiatrice.Il Sistema di pulizia separato delle 4 cartucce indipendenti consente la massima efficienza del Sistema in ogni momento delle Vostre lavorazioni. iVision© touch screen system permette il pieno controllo dell’impianto e della sua efficienza in maniera facile ed intuitiva. -

SAND TR

Sand LineINDUSTRIAL VACUUM CLEANERS FOR SAND

The TR vacuum cleaners, from the Sand line, are used for the collection of dust and sand-blasting in industrial environments, where efficient extraction is required in order to keep the working environment clean and the operators’ health protected. The collection hopper allows the material to be stored and the manual valve at the base facilitates its discharge directly into the sandblaster by moving the vacuum cleaner via the lifting supports. -

SANDBLASTING CLEANING KIT

AccessoriesHI-TECH VACUUM

For office or the work environment at the end of the day cleaning, iVision has developed a cleaning kit particularly robust dedicated to the sandblasting world. This version can be enlarged according to the specific needs of the client and can be easily attached through special supports on the side of the vacuum, this also helps avoid the tube from impeding the vacuum movement. -

-

SHOES 320

皮革和鞋类INDUSTRIAL VACUUM CLEANER FOR DUST OF LEATHER & FABRICS

The SHOES 320 litres vacuum cleaner is an excellent system used in the shoemaking world for the industrial extraction of grinding, carding or brushing machines. Vacuum cleaners in the SHOES line basically cover all of the chip extraction needs on machine tools in the shoe production world and from leather and fabric processing, combining the attention and care of design with simple and sturdy materials. The use of a cyclonic pre-filter captures more than 90% of the suctioned material before it reaches the main filter, thus preventing it from clogging and considerably extending its life. -

SPECIAL KIT FOR FLOOR CLEANING

AccessoriesHI-TECH VACUUM

For floor cleaning, iVision has developed a specific kit with a fixed brush positioned on the front part of the vacuum with a handle for manuevering. -

TOUCH SCREEN

AccessoriesHI-TECH VACUUM

The vacuum cleaner is equipped with a touch screen unit on the front. It allows the operator to quickly and easily monitor the level of contamination of the filter. Thanks to such a device, the operator is able to recognize in real time the filter condition and the efficiency of the whole vacuum cleaner. Afterwards, the operator can choose to clean the filter (in manual or automatic mode) and also manage the remote Start&Stop control option. Once the filter is completely clogged, the unit will automatically warn the operator of the need to replace the filter utilizing: • A visual signal -

WOOD 165

木工专用吸尘器INDUSTRIAL VACUUM CLEANER FOR WOOD AND PVC CHIPS

The 165 industrial vacuum cleaners WOOD line are mainly used to collect and capture large volumes of dust, wood shavings and PVC chips. They are designed to be combined with circular saws, thickness planers, grinders or graders, cutters and vertical panel saws. Their filter surface area is high and they are equipped with M-class bag filters. In addition, the compressed air filter cleaning system makes it easy to clean the filters whenever necessary, facilitating regular maintenance. WOOD 165 vacuum cleaners are also equipped with a separator unit to protect the filter area and optimise the storage of the sucked material in the collection containers, which are characterised by their large tank capacity. -

WOOD 180,单料袋

木工专用吸尘器WOOD LINE

WOOD系列的180单袋工业吸尘器主要用于收集和捕获灰尘、木屑和PVC碎屑,并与圆锯、厚刨床、研磨机或校准器、刀具相配套。由于吸尘器的结构构造,离心风机的高性能得到充分利用,产生了极其高效的抽吸效果。这些工业吸尘器达到较大流量值,使用在吸口直径(200mm+)的机器上使用。使用抗划伤的PVC袋,便于收集粉尘和所有提取的材料。 -

WOOD 330

木工专用吸尘器INDUSTRIAL VACUUM CLEANER FOR WOOD AND PVC CHIPS

The 330 industrial vacuum cleaners WOOD line are mainly used to collect and capture large volumes of dust, wood shavings and PVC chips. They are designed to be combined with circular saws, thickness planers, grinders or graders, cutters and vertical panel saws. Their filter surface area is high and they are equipped with M-class bag filters. In addition, the compressed air filter cleaning system makes it easy to clean the filters whenever necessary, facilitating regular maintenance. WOOD 330 vacuum cleaners are also equipped with a separator unit to protect the filter area and optimise the storage of the sucked material in the collection containers, which are characterised by their large tank capacity. -

WOOD 360,双料袋

木工专用吸尘器WOOD LINE

WOOD系列的360双袋工业吸尘器主要用于收集和捕获灰尘、木屑和PVC碎屑,并与圆锯、厚刨床、研磨机或校准器、刀具相配套。由于吸尘器的结构构造,离心风机的高性能得到充分利用,产生了极其高效的抽吸效果。这些工业吸尘器达到较大流量值,使用在吸口直径(200mm+)的机器上使用。使用抗划伤的PVC袋,便于收集粉尘和所有提取的材料。 -

WOOD 495

木工专用吸尘器INDUSTRIAL VACUUM CLEANER FOR WOOD AND PVC CHIPS

The 495 industrial vacuum cleaners WOOD line are mainly used to collect and capture large volumes of dust, wood shavings and PVC chips. They are designed to be combined with circular saws, thickness planers, grinders or graders, cutters and vertical panel saws. Their filter surface area is high and they are equipped with M-class bag filters. In addition, the compressed air filter cleaning system makes it easy to clean the filters whenever necessary, facilitating regular maintenance. WOOD 495 vacuum cleaners are also equipped with a separator unit to protect the filter area and optimise the storage of the sucked material in the collection containers, which are characterised by their large tank capacity. The vacuum cleaner is equipped with a fire kit that automatically intervenes if a high temperature rise is detected within the system. -

WOOD CUSTOM

木工专用吸尘器INDUSTRIAL VACUUM CLEANER FOR WOOD AND PVC CHIPS

The CUSTOM model is dedicated to intensive and continuous machining on automatic cutting centres with high chip production. Thanks to the discharge system with rotary valve it is used in all working environments where, due to production requirements, suction is required 24/7. The vacuum cleaners can be supplied with different accessories to make work easier in large manufacturing companies. Each model has been designed, developed and assembled to meet the specific requirements of each customer, focusing above all on the realisation of a product able to work side by side with each customer's machine tools. The careful study of details, the attention dedicated to design, the use of strong materials and the production of a simple but high-performance model are the features of a product entirely developed and manufactured in Italy.