-

额外容器

AccessoriesIVISION 工业真空吸尘器配件

如果42升的吸尘器标准容量不足,iVision可以为客户提供额外的高容 量碎屑容器。 iVisin开发了2类容器: A) 1000升容器,打开有自动开口 B) 500升容器,打开有手动开口 该容器配有可视填充指示器,为操作人员显示清空容器的时间。 -

-

消防套件

AccessoriesIVISION 工业真空吸尘器配件

该配件是一种在收集箱内温度持续升高时自动介入的装置,通过喷嘴排空收集箱内的空气和水混合物。如果系统没有自动启动,则可以通过相应的按钮手动启动。 -

防静套件

AccessoriesIVISION 工业真空吸尘器配件

适用于所有型号的在产工业真空吸尘器。使用该套件可以卸载收集阶段积累的静电荷,避免将其转移到其他机器或操作人员身上。 考虑到铝屑会在罐内产生潜在的爆炸性气体,因此在处理铝时特别推荐使用该套件。 -

摇晃自动清洗

AccessoriesIVISION 工业真空吸尘器配件

使用气动活塞清洗过滤器时,需要连接一个 6-8 巴的空气适配器,并通过一个压力调节器来改变活塞的滑动强度。 - 为了有效清洁安装在真空机内的过滤器,我们开发了垂直活塞式过滤器清洁系统。通过手动选择器(半自动解决方案)或定时器(自动版本),气动活塞从过滤器底部开始动作,以确保转移到过滤器外部的碎屑或灰尘落入收集槽,从而使过滤器继续保持最佳功能。 - 垂直活塞式清洁过滤器适用于任何类型的应用,因为与振动电机标准版相比,它能显著改善过滤器的清洁效果。 - 过滤器的垂直活塞清洁,尤其是在自动型过滤器中,在吸入可能会迅速堵塞过滤器的细小灰尘时是必须的。对于大块和重型切屑,该系统不是强制性的,但对于轻型或易挥发材料,则是强制性的! - 该系统的主要优势在于活塞震动过滤器的效率更高。另一个优点是使用该系统的自动版本,每次关闭电机时都会摇动过滤器,消除了操作员可靠性的典型问题,因为操作员通常必须记住打开过滤器的清洁功能。 -

喷砂分离篮

AccessoriesIVISION 工业真空吸尘器配件

这是一个由多孔板制成的筛子,可以在抽吸过程中截留喷砂过程中产生的残留物和一般污物。它有两个舒适的手柄,便于取出容器和清空容器后重新放置。 -

液体分离器

AccessoriesIVISION 工业真空吸尘器配件

润滑油金属网屑分离器。 该选配附件可将吸入的固体物质与液体完美分离,便于储存和/或处理。 金属网屑分离器可吸附固体物质,使液体沉积到收集槽底部。 -

清洁套件 Ø 50 毫米

AccessoriesIVISION 工业真空吸尘器配件

清洁套件可以用于所有系列,采用坚固的耐磨管道,端部配备特制镀锌配件,能够毫无障碍的 从机床向真空收集缸运输碎屑和油。 真空抽吸管道能够方便的存放在外部支架上,便于移动,避免干扰操作人员。此外,还可以避免在真空操作过程中的漏油情形。 -

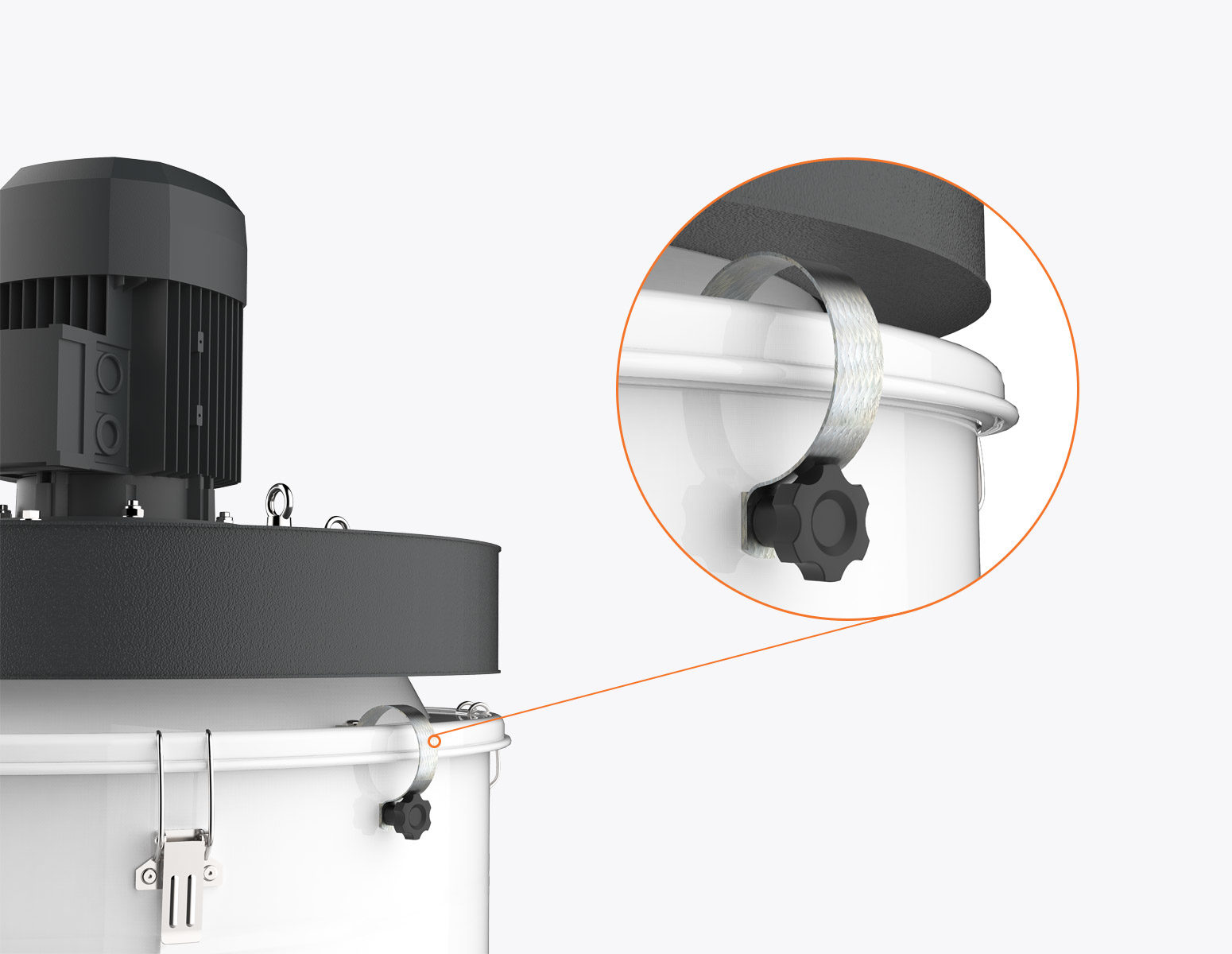

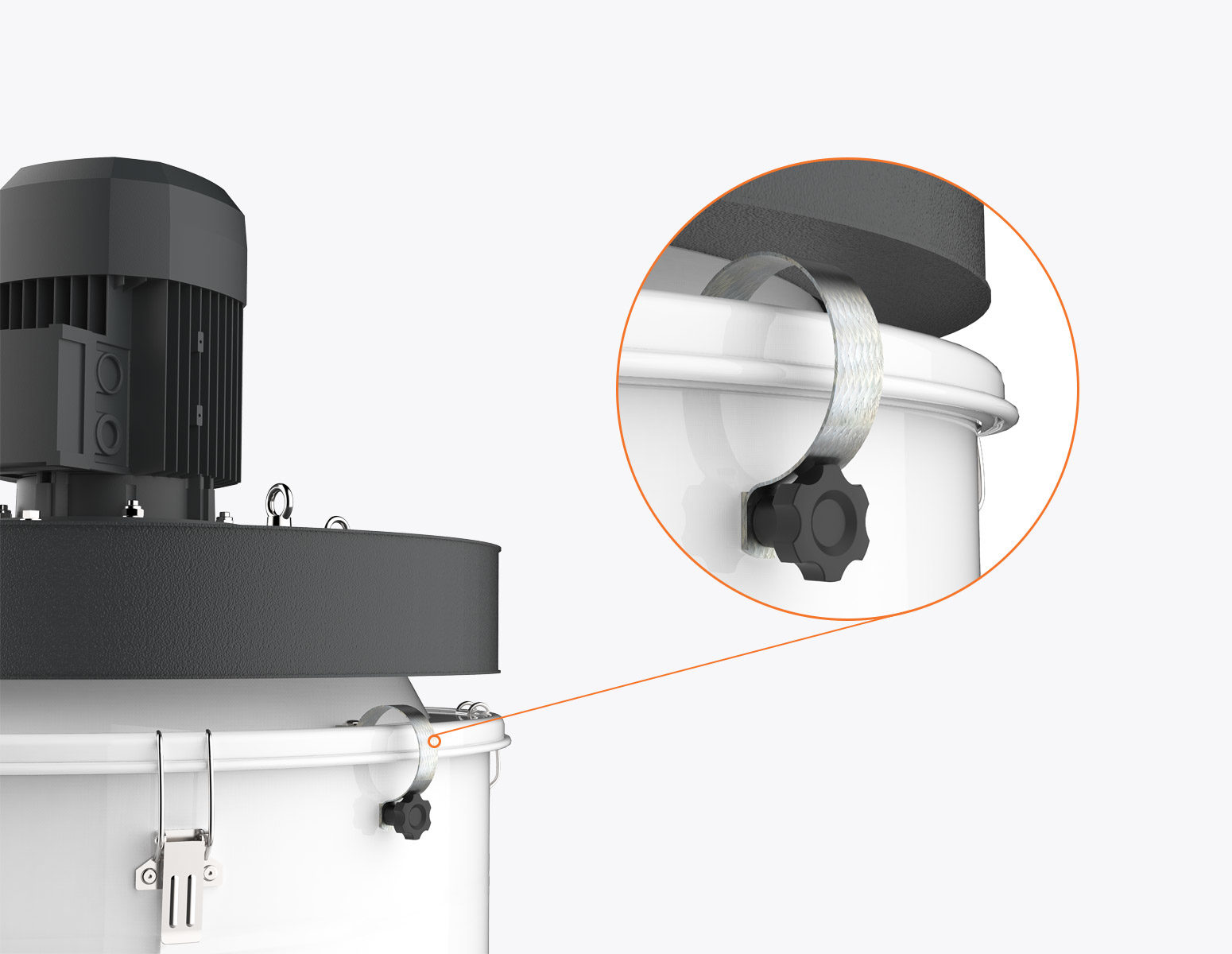

旋风分离器 预过滤器

AccessoriesIVISION 工业真空吸尘器配件

强烈建议尽可能将其连接到真空吸尘器的上游,作为吸入物的第一收集点。 专门用于保持真空吸尘器内部过滤器的使用寿命。 它保留了大部分吸入的材料,形状可以是圆锥形或圆柱形,起到机械过滤器的作用。 通过切向入口,吸入的材料在内部被离心,直到其速度逐渐降低,材料在重力的作用下落到收集装置的底部。 这一过程确保只有相对较低比例的吸入灰尘或碎屑真正到达位于吸尘器顶部的过滤器。 旋风式预过滤器对于细小或极细小的灰尘几乎是强制性的,因为这些灰尘会堵塞过滤器,影响整个系统的正常运行,但只建议用于大块、重型碎屑。旋风式预过滤器的主要优点是可以保护真空吸尘器的过滤器不被堵塞,从而延长其更换前的使用寿命,并大大减少整个系统的维护工作。 -

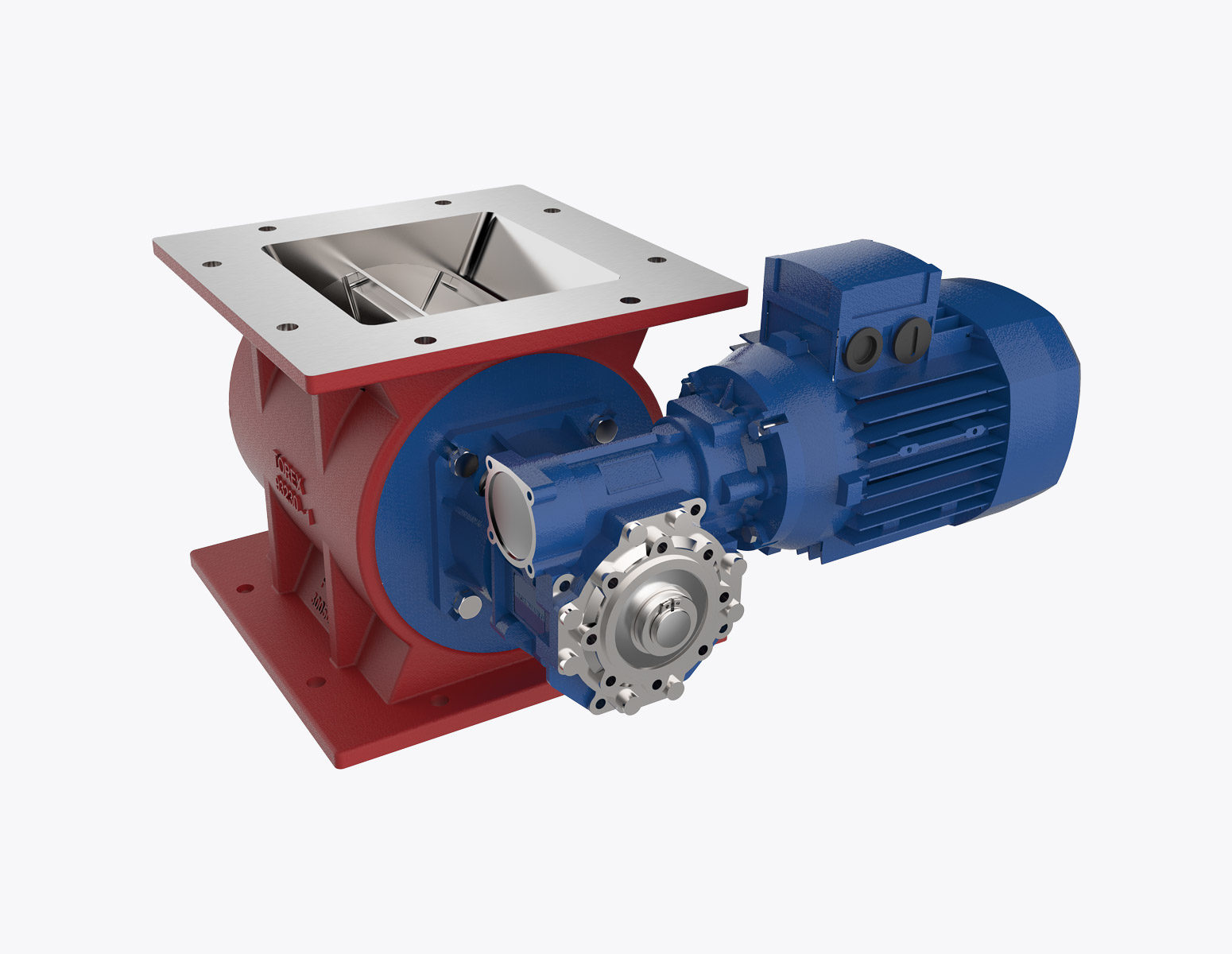

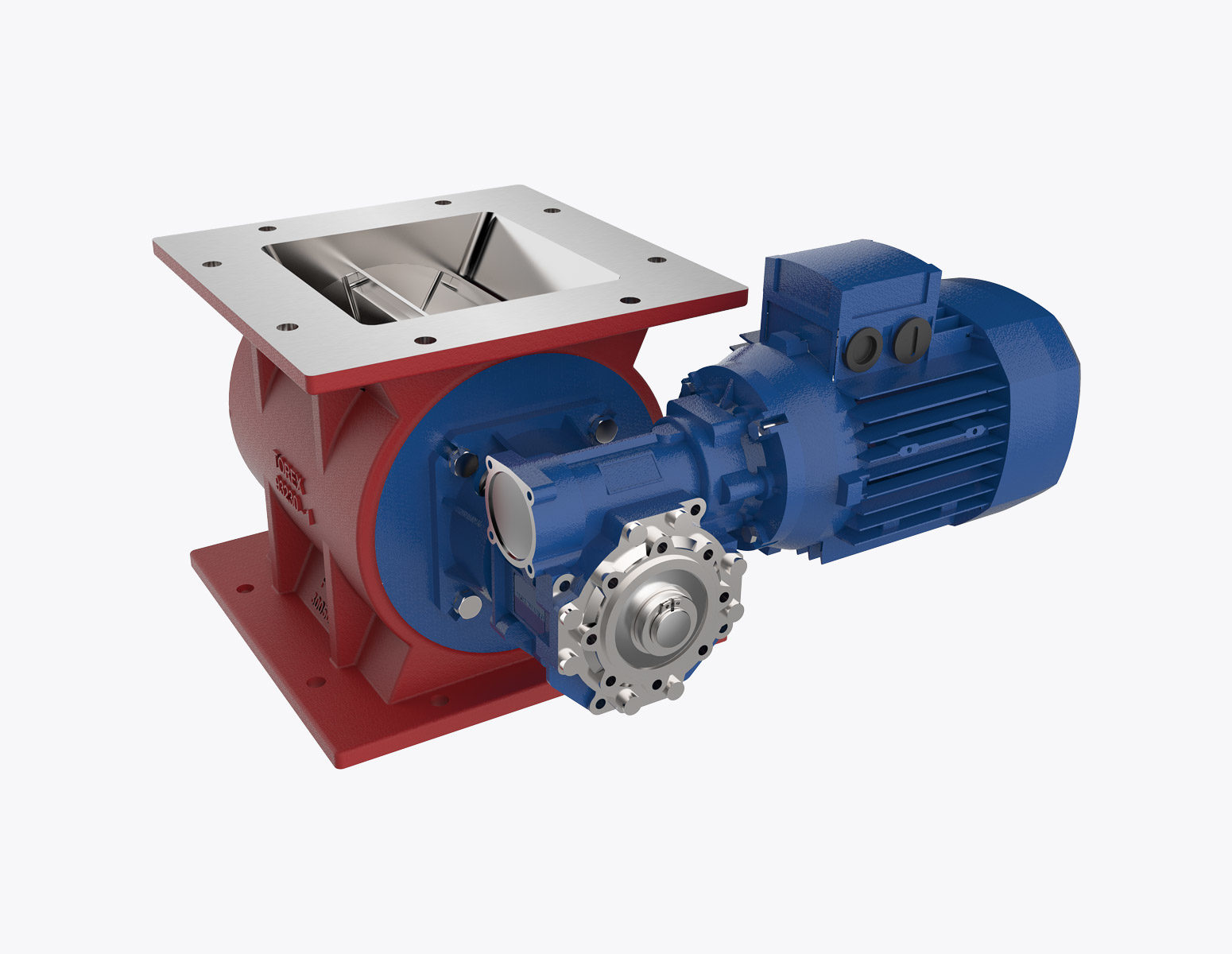

EMPTYING ROTARY VALVE KIT FOR CONTINUOUS WORK

AccessoriesHI-TECH VACUUM

For those that need a continuous work cycle in construction environments and need to empty without interrupting work due to turning off the vacuum to empty the collection container, the iVision rotary valve kit is an interesting solution. -

真空吸尘器过滤器

AccessoriesIVISION 工业真空吸尘器配件

真空吸尘器和粉末排放到环境中的分类过滤器是根据粉末的类型和对健康的危害程度来划分的。全球范围内的 IEC 60335-2-69 标准对吸尘器的此类分类做出了规定。 该分类提供了多个粉末类别,例如 - 粉末 L 类(低度/中度):属于 MPC 值(工作场所最大允许浓度)为 1 mg / m³ 的粉末,至少保留 99% 的吸入颗粒。 - 粉末类别 M(中):属于 MPC 值(工作场所最大允许浓度)为 0.1 mg / m³ 的粉末和木粉,吸入的颗粒至少保留 99.9%。 - 粉末类别 H(高):属于 MPC 值(工作场所最大允许浓度)< 0.1 mg / m³ 的粉末,致癌和致病粉末至少占吸入颗粒的 99.995%。每台 iVision 真空吸尘器上都贴有标签,标明允许吸入环境中粉尘的危险等级。 -

频率逆变器

AccessoriesIVISION 工业真空吸尘器配件

紧凑、高效、经久耐用的技术。频率逆变器能够调整和管 理Ivision吸尘器的性能。 该逆变器能够实际管理风机的正常工作或在各种可能的紧 急情况下瞬时干预,增大或减小电机转速,以确保设备具 有安装所需的性能。 例如,当风机断裂或过滤器堵塞时,抽吸功率下降,此时感应器启用逆变器,增大电机转速,以补偿功率损失。 因此,如果设备与厂房相连,则可以预防停产或损坏加工中工件的情形。 除了确保设备性能之外,还能优化耗电量,例如,能够监控机床是否的确正在加工,由此将整台设备的能耗降低至最小必须水平。 可靠性和简洁性无可媲美,也可编程以执行更加复杂的操作,此外,能够避免抽吸空气与电子部分相接触。 -

门 密封

AccessoriesIVISION 工业真空吸尘器配件

门阀能够关闭多个通风口,允许操作人员选择使用一个、两个或多个管道同时工作。 这些通风口可以由操作人员手动操作、由机器自动操作、或通过脚踏板远程操作。 -

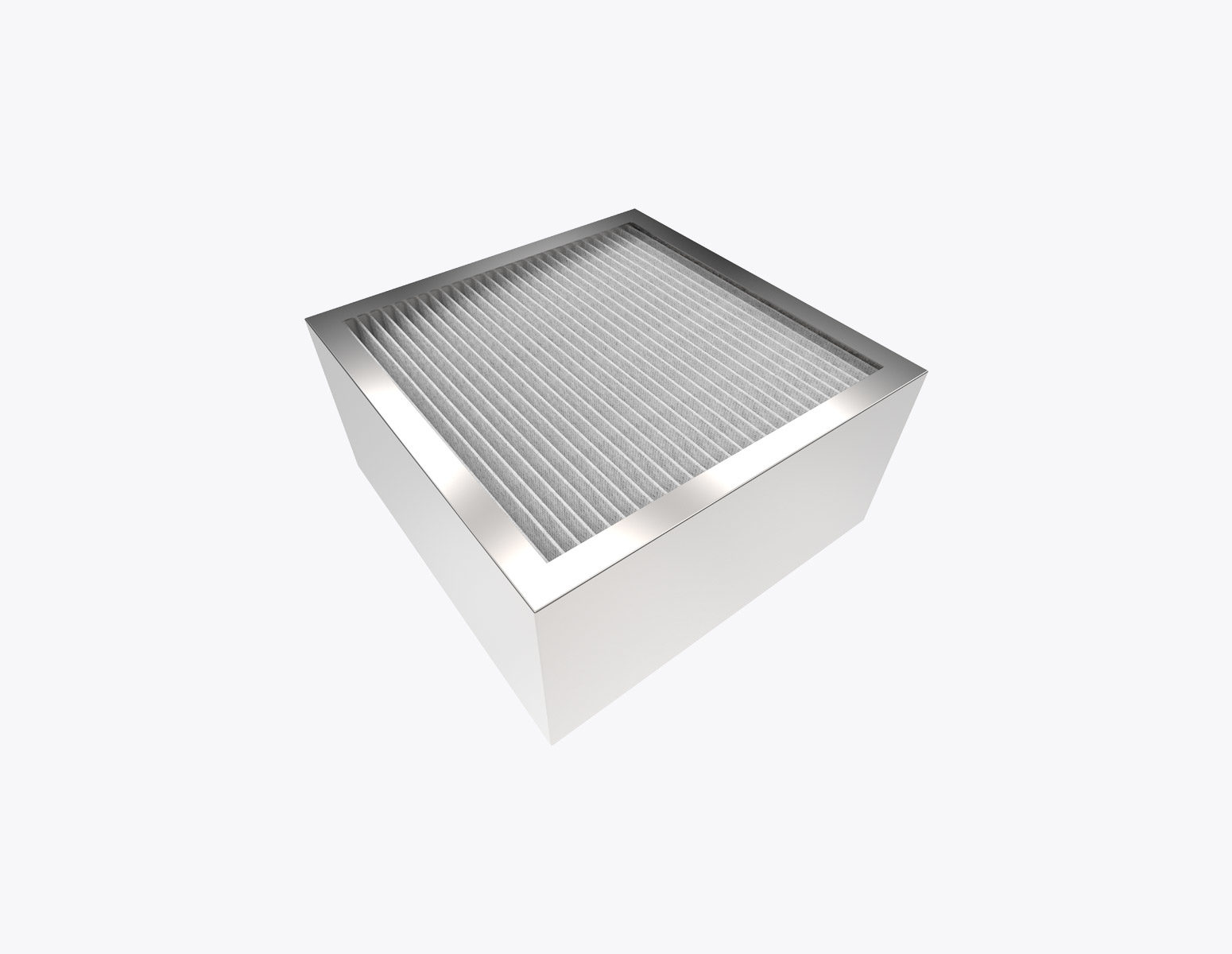

过滤 Hepa

AccessoriesIVISION 工业真空吸尘器配件

HEPA 是 "高效微粒空气 "定义的缩写。 它是一种用于吸尘器的过滤器,具有对流体、液体或气体进行高效过滤的特殊系统。它能够捕获大量极小尺寸的颗粒,这是其他吸尘器过滤器所不具备的。事实上,过滤器有不同的类别(L/M/H),HEPA 过滤器也有不同的类别,根据材料的不同,吸入效率也不同。 HEPA 过滤器由多层组装的超细纤维过滤片(一般为硼硅酸盐)组成,并由铝隔板隔开。微纤维过滤片的任务是阻挡污染性固体颗粒(或微粒)。这些固体颗粒非常小,可能对健康有害或影响最终产品的质量。 HEPA 过滤器属于 "绝对过滤器 "的范畴,因为这种过滤器的过滤效率很高。HEPA 过滤器的过滤效率在 85% (H10) 到 99.995% (H14) 之间。UNI EN 1822 标准规定了 0.3 µm 微粒的过滤效率。 -

升降机成套设备

AccessoriesIVISION 工业真空吸尘器配件

该吊运套件可以用于100升(iV2)或160升(iV3)碎屑容器,将容器与叉车通过安全链条相连,便于运输。 操作人员无需在收集缸清空过程中过度用力。 在劳动保护法极为严格并指定操作人员能够举 起的最大重量的所有国家均建议使用该配件。 如果重量超过法定限值,则必须使用本配件。 -

远程 启动停机

AccessoriesIVISION 工业真空吸尘器配件

该套件能够与机床同步自动开关吸尘器。 有三种不同方式: a) 在停电“无触点”情况下开机。 b) 通过24V触点开机。 c) 通过230V触点开机。 -

喷砂清洁套件

AccessoriesIVISION 工业真空吸尘器配件

针对办公室或工作环境的日常清洁工作,iVision 开发了一种特别坚固的清洁套件,专用于喷砂领域。 该套件可根据客户的具体需求进行扩展,并可通过真空吸尘器侧面的特殊支撑轻松安装,这也有助于避免管子阻碍真空吸尘器的移动。 -

-

触摸屏

AccessoriesIVISION 工业真空吸尘器配件

吸尘器前方配备触摸屏。操作人员能够简而快速的监控过滤器污染水平。 凭借该装置,操作人员能够实时评估过器状态和吸尘器整体效率。之后,操作人员可以选择清洁过滤器(手动或自动,也可管理远程启动选项。 当过滤器完全堵塞时,该系统将通过下列方式自动通知操作人员更换过滤器: • 音频信号。 • 视觉信号。