-

EXTRUSION 160

LINHA EXTRUSIONASPIRADORES INDUSTRIAIS PARA APARAS DE ALUMÍNIO E PVC

Os aspiradores 160 da linha Extrusion são os modelos iVision mais vendidos graças à sua versatilidade. Tratam-se de excelentes sistemas usados juntamente com máquinas de corte de cabeça dupla ou centros automáticos de corte com elevada produção de aparas e pó. Graças à muito ampla gama de aspiradores industriais e as quase infinitas possibilidades de personalização, iVision consegue satisfazer quase todas as exigências de aspiração de resíduos em máquinas de ferramentas no mundo da extrusão unindo a atenção ao design a materiais simples e robustos. Os 160 são os aspiradores escolhidos por quem exige o melhor em termos de desempenho, eficiência e inovação no ambiente de trabalho. -

EXTRUSION 320

LINHA EXTRUSIONINDUSTRIAL VACUUM CLEANERS FOR METAL & PVC CHIPS

The 320 vacuum cleaners of the Extrusion line are designed specifically for industrial purposes, this model is equipped with powerful motors and an advanced filtering system.Its vacuum characteristics and air flow rate make it ideal for the suction of chips or dust.The use of a cyclonic pre-filter captures more than 90% of the suctioned material before it reaches the main filter, thus preventing it from clogging and considerably extending its life. -

EXTRUSION 38

LINHA EXTRUSIONASPIRADORES INDUSTRIAIS PARA APARAS DE ALUMÍNIO E PVC

Os aspiradores iV1 da linha Extrusion são os mais compactos da gama iVision. Usados juntamente com pequenas máquinas de corte de cabeça individual com baixa produção de aparas e pó. Desempenham perfeitamente a aspiração de materiais ligeiros, tais como PVC, alumínio e outras ligas. As dimensões compactas dos iV1 permitem ao operador de mover-se com agilidade em espaços restritos mantendo um padrão de qualidade excelente em termos de eficácia de aspiração e eficiência de filtração. Graças aos motores trifásicos estes aspiradores podem operar tranquilamente continuamente com a mínima manutenção. -

EXTRUSION CUSTOM

LINHA EXTRUSIONINDUSTRIAL VACUUM CLEANER FOR METAL AND PVC CHIPS

The CUSTOM vacuum cleaners of the Extrusion line are among the most advanced models in the iVision range and are usually used together with automatic cutting centres.This vacuum cleaner is equipped with a high flow rate fan (pressurised system) that extracts large amounts of chips, which are continuously discharged.This occurs thanks to the continuous discharging system into big bags through a rotary valve.An innovative system of filling sensors is able to provide the operator with an alarm when the bigbag is about to fill, so that the operator can replace the bigbag in time and prevent the machine from stopping. -

FILTER

AccessòriosHI-TECH VACUUM

The classification filters for vacuum cleaner and powders emissions into the environment, is assigned by the type of powders and the degree of danger to health. For its suction devices such classification is regulated by IEC 60335-2-69 worldwide. This classification provides several categories of powders, such as: • Category of powders L (low/moderate): fall into that category powders with MPC values (maximum permitted concentration in the work place) > 1 mg / m³Are retained at least 99% of particles aspirated.The disposal of the collected material must be made trying to raise a few powders. • Category of powders M (medium): fall into that category powders with MPC values (maximum permitted concentration in the work place) > 0.1 mg / m³ and wood powdersAre retained at least 99.9% of particles aspirated.The disposal of the collected material must be made trying to raise a few powders. • Category of powders H (high): fall into that category powders with MPC values (maximum permitted concentration in the work place) < 0.1 mg / m³, with carcinogenic and pathogenic powdersAre held at least 99.995% of particles aspirated.The disposal of the collected material must be done without raising powders. On each iVision vacuum cleaner is applied a label indicating the hazard class of the dust in the environment allowed. -

FLAT TABLE 100

LINHA FLAT TABLEASPIRADORES INDUSTRIAIS PARA MÁQUINAS DE CONTROLO NUMÉRICO

Os aspiradores industriais da linha FLAT TABLE 100 de iVision são os modelos com ventilador lateral mais vendidos para o uso no mundo do processamento de painel. Apesar de ser de dimensões compactas, para facilitar o uso também em espaços estreitos, os aspiradores FLAT TABLE 100 têm um reservatório de 100 litros: isto faz com que sejam usados juntamente com máquinas de fresar de 3 eixos que geram uma relevante quantidade de resíduos e material a aspirar para garantir o seu correto processamento. -

FLAT TABLE 160

LINHA FLAT TABLEASPIRADORES INDUSTRIAIS PARA MÁQUINAS DE CONTROLO NUMÉRICO

Os aspiradores da linha FLAT TABLE 160 são os modelos de maior desempenho da gama iVision e são ideais para a recolha de resíduos nas grandes máquinas CNC. Graças aos muito potentes ventiladores de canal lateral e ao grande coletor para aparas (160l), os aspiradores da linha FLAT TABLE 160 são ideais para a manutenção e limpeza de grandes centros de trabalho com elevada produção de resíduos, aparas e pó. Os resíduos gerados pelas fresas nas máquinas de 3 eixos de controlo numérico requerem uma aspiração industrial das aparas e do pó o mais eficiente possível, para garantir o correto processamento da máquina de ferramenta. A integração de acessórios especificamente realizados para este sector, como por exemplo o inovador braço aéreo, permite a iVision de poder fornecer o correto produto para cada aplicação. O uso de componentes altamente tecnológicos juntamente a uma minuciosa atenção para o design caracterizam todos os aspiradores industriais iVision. -

FLAT TABLE 320

LINHA FLAT TABLEINDUSTRIAL VACUUM CLEANER FOR CHIP ON CNC ROUTER.

The FLAT TABLE 320 model is used in the world of machining with 3-axis CNC machines with high dust/chip production. Designed specifically for industrial purposes, this model is equipped with powerful motors and advanced performing filtration system.Its vacuum and airflow characteristics make it ideal for heavy dust extraction.The use of a pre-filter-cyclone enables it to capture more than 90% of the sucked material before it reaches the main filter, thus preventing clogging and greatly extending its service life. -

FLAT TABLE 38

LINHA FLAT TABLEASPIRADORES INDUSTRIAIS PARA MÁQUINAS DE CONTROLO NUMÉRICO

Os aspiradores da linha FLAT TABLE 38 são os modelos mais compactos e práticos entre os aspiradores industriais iVision. Tratam-se de aspiradores industriais com ventilador de canal lateral, usados para a recolha de aparas nas pequenas máquinas CNC. Os resíduos gerados pelas máquinas de fresar de 3 eixos necessitam de uma aspiração industrial de aparas muito eficiente para garantir a limpeza absoluta. As dimensões compactas permitem ao operador de se mover com agilidade em espaços estreitos. O excelente desempenho dos ventiladores de canal lateral é, deste modo, plenamente usufruído. -

FREQUENCY INVERTER

AccessòriosHI-TECH VACUUM

Compact technology, powerful and built-to-last this characterizes the frequency inverter that regulates and manages the performance of iVision vacuums. The inverter operates the normal work of the turbines or intervenes instantaneously in all of the possible emergencies that may occur by increasing or decreasing the RPM of the engines in order to ensure the same performance for the system even in the case that a machine that the vacuum is attached to stops working. -

GATE CLOSURE

AccessòriosHI-TECH VACUUM

The gate valves that enable the closure of multiple vents allow the operator to choose to work with one, two or more hoses simultaneously. These gates can be operated manually by operators, handled automatically by machines, or remotely via foot pedal. -

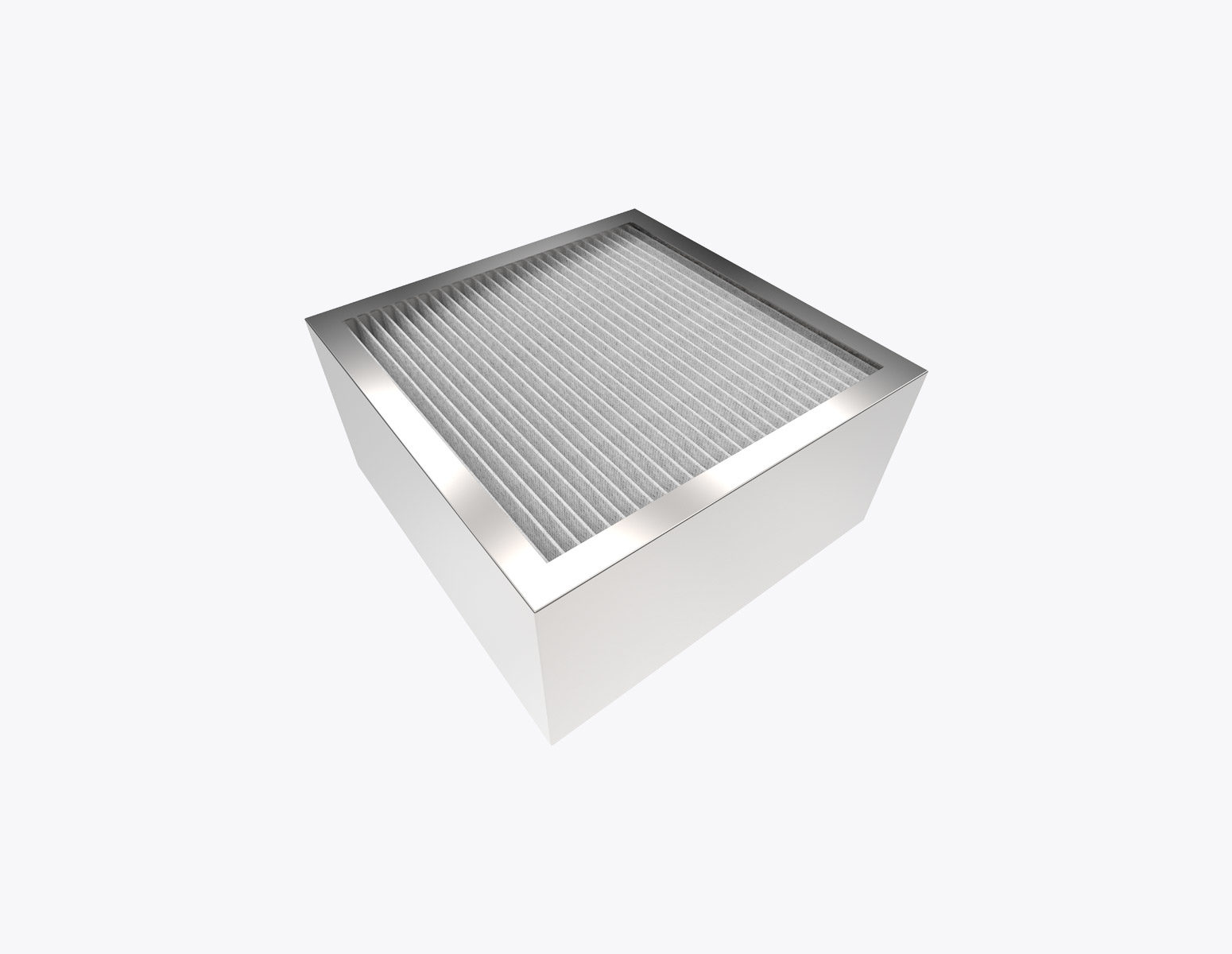

HEPA FILTER

AccessòriosHI-TECH VACUUM

HEPA is the acronym used for the definition “High Efficiency Particulate Air”. It ‘a kind of filter for vacuum cleaner with a particular system of filtering with high efficiency for fluid, liquid or gas. It has the ability to trap a very high amount of particles of very small size, ability that other filters for vacuum cleaners do not have. Indeed, there are different categories of filters (L / M / H), and different categories of HEPA filters, that has made according to the material more efficient to inhale. The HEPA filter is composed from microfiber filter sheets (generally borosilicate) assembled in multiple layers, and separated by aluminum septa. The microfiber filter sheets have the task to block the polluting solid particles (or particulate). The solid particles are very small and can be harmful to health or may affect the quality of the final product to be obtained. HEPA filters are part of the category of the “absolute filters”, justified by the fact that these filters have a high efficiency of filterign. In particular, HEPA filters introduce an efficiency of filtering between 85% (H10) and 99.995% (H14). The filtration efficiency of particles of 0.3 µm, is regulated by the UNI EN 1822.