![]()

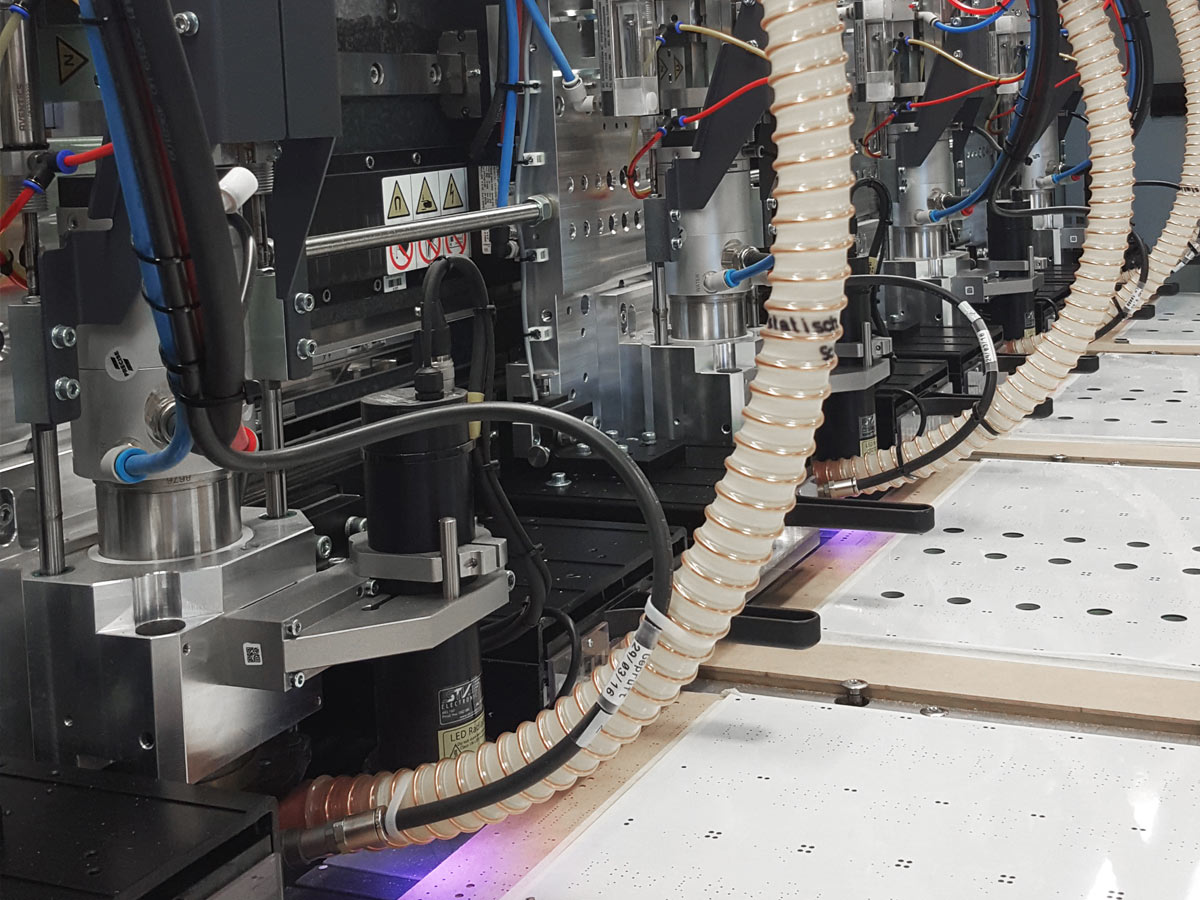

PCB LINE

Industrial Vacuum Cleaners for Aluminum and glass fiber

This range of models is used with great success in the world of printed circuit board processing. Thanks to the use of high-performance side channel blowers, our industrial vacuum cleaners ensure a particularly efficient and constant suction thus guaranteeing an impeccable end-product that, during its processing, is completely free from chips or dust.

Numerous tests, high-tech patents and attention to details allow iVision to be among the global benchmark suppliers in this product segment.

The excellence of the design and construction techniques creates an extremely agile system, capable of adapting to various spaces and needs. Both the wheeled vacuum cleaners and the centralized systems are easy to use and practically maintenance-free, thanks to the innovative technical solutions used to protect the units over time.

The PCB line is suitable for machine tools, automatic machining centers (CNC), drilling machines and general cleaning. Optional accessories such as the Touch Screen system have been developed specifically for the Printed Circuit sector.

PCB LINE PRODUCTS

____________________

Suctioned materials

Do not hesitate to contact us for a personalized quote, we will be able to guide you towards the product that best suits your needs.

The power of innovation