The woodworking industry represents a delicate balance between craftsmanship and technological innovation, constantly adapting to meet the evolving demands of the market. From furniture production to panel processing, woodworking generates fine dust, waxy residues, and foamy substances. If not managed properly, these by-products can compromise worker safety, reduce productivity, and affect the quality of the final product.

In this case study, we explore how iVision Vacuum developed a customized vacuum solution for a company specializing in wood processing. The tailored system successfully addressed all their requirements.

Types of waste from wood material processing

The client, an expert in wood materials, faced significant challenges in managing waste generated from contouring and drilling operations on horizontal CNC machines. The primary types of waste included:

- MDF (Medium density fibreboard)

This wood composite is extremely fine and volatile, posing health risks to operators and challenges for extraction systems.

- Waxy and foamy residues

Surface treatments on wood generate these residues, which quickly compact with dust, obstructing filters and reducing system efficiency.

This combination of waste materials necessitated a vacuum solution designed to tackle specific technical challenges.

The specific suction requirements of the woodworking company with a contouring and drilling process

The woodworking company identified several key challenges that required a vacuum system capable of:

- Handling MDF waste volatility: High-performance filters were essential to capture at least 99.9% of fine particles, preventing health and environmental hazards.

- Clearing waxy and foamy residues without blockages: Automatic filter cleaning mechanisms were necessary to remove clogs without frequent manual intervention.

- Ensuring continuous operation: The system had to operate seamlessly with CNC machines, supporting intensive production cycles without impacting productivity.

- Adapting to various workstations: Flexible solutions were required to accommodate different suction diameters and distances between machines and the collection unit.

- Enhancing safety and cleanliness: The system had to reduce airborne dust in compliance with safety regulations, improving operator comfort.

These needs guided iVision Vacuum in developing a custom Flat Table Line solution that fully met the client’s requirements while enhancing overall production efficiency

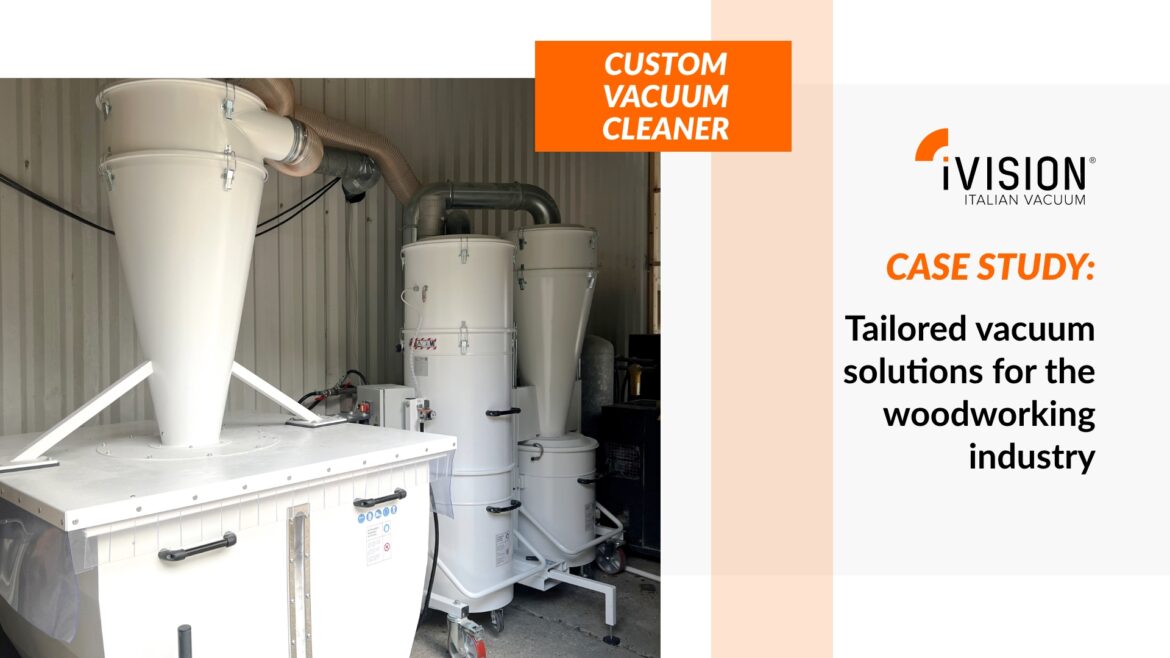

Customized Flat Table 320 vacuum cleaner for woodworking

To address the client’s specific needs, iVision Vacuum delivered a tailored solution based on the Flat Table Line, renowned for its power, reliability, and safety features. The chosen model, Flat Table 320 (12.5 kW), was customized with:

- 12.5 kW suction power

Designed for continuous and efficient handling of large volumes of MDF waste.

- Automatic cartridge filter cleaning system

Programmed for operation during and after work to maintain optimal performance and prevent blockages.

- 1000-Liter collection container

Reduces operational interruptions for emptying.

- Dual cyclonic pre-separators

Prevents highly volatile and compacting waste from reaching and clogging the filter.

- Internal cyclone accelerator

Enhances material deceleration for efficient deposition before reaching the main filter, prolonging filter lifespan.

- Connection to two CNC machines

Provides centralized, high-performance waste management.

These features enabled the Flat Table 320 to optimize waste management, improve workplace safety, and extend the lifespan of the vacuum system.

Optimize your operations with iVision Vacuum

Are you looking for a vacuum solution tailored to your woodworking needs? Discover how iVision Vacuum can enhance efficiency and safety in your production facility. Contact us today for a personalized consultation.