When you buy a vacuum cleaner, you generally pay attention to its technical characteristics, such as the engine power, the types of materials sucked in, the capacity of the container, the air flow and the head. In rare cases, we focus on the filtration system present in the machinery.

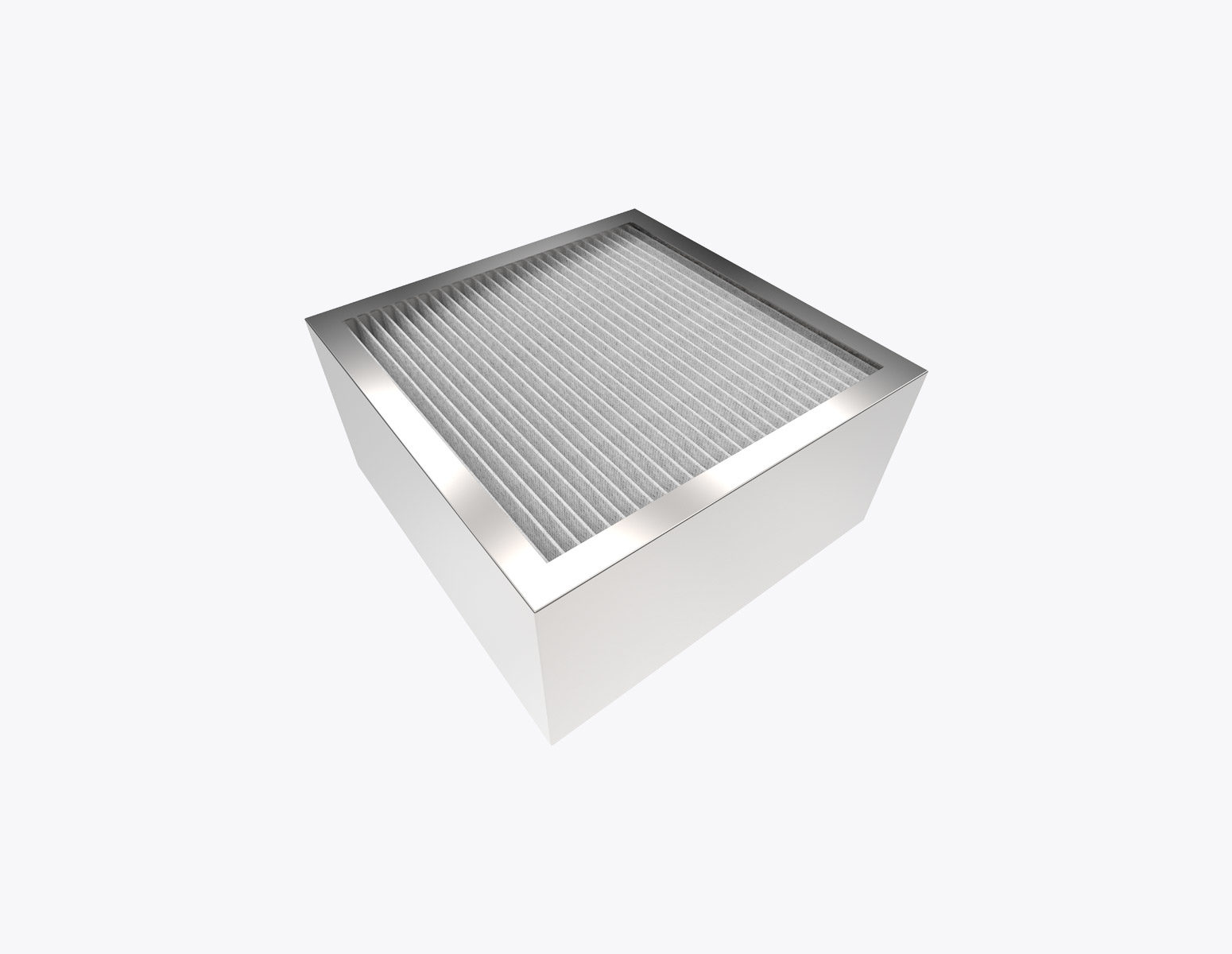

Still, the filter is one of the most important parts of the industrial vacuum cleaner. This is because the quality of the air that is reintroduced into the workplace and, therefore, the safety and health of the operators depend on it. Furthermore, another essential function of the filter is to protect the suction head (whether this consists of a fan or a side channel blower), the beating heart of the suction unit, to prevent it from being damaged by the sucked material.

Depending on the type of dust and its level of danger, the filters are divided into different categories according to the IEC 60335-2-69 regulation:

- Class L: moderate risk. The filter is capable of retaining 99% of dust smaller than 2 microns. This classification includes dusts with MAC values (Maximum Allowable Concentration in the workplace) bigger than 1 mg/m3.

- Class M: medium risk. The filter is capable of retaining 9% of dust smaller than 2 microns. This classification includes dust with MAC values bigger than 0.1 mg/m3 and dust derived from wood.

- Class H: high risk. The filter is capable of retaining 995% of dust smaller than 1 micron. This classification includes dusts with MAC values lower than 0.1 mg/m3, carcinogenic dusts and those contaminated with pathogens.

The filtering system of your industrial vacuum cleaner is therefore not a trivial matter. For this, at iVision Vacuum we use very high quality filters, capable of capturing any impurity or particle. To prevent these from being reintroduced into the work environment and therefore putting workers’ health at risk, it is necessary that the filter is cleaned often, making sure that it works properly.

Contact us to find out more about the most suitable filter for your industrial vacuum cleaner!