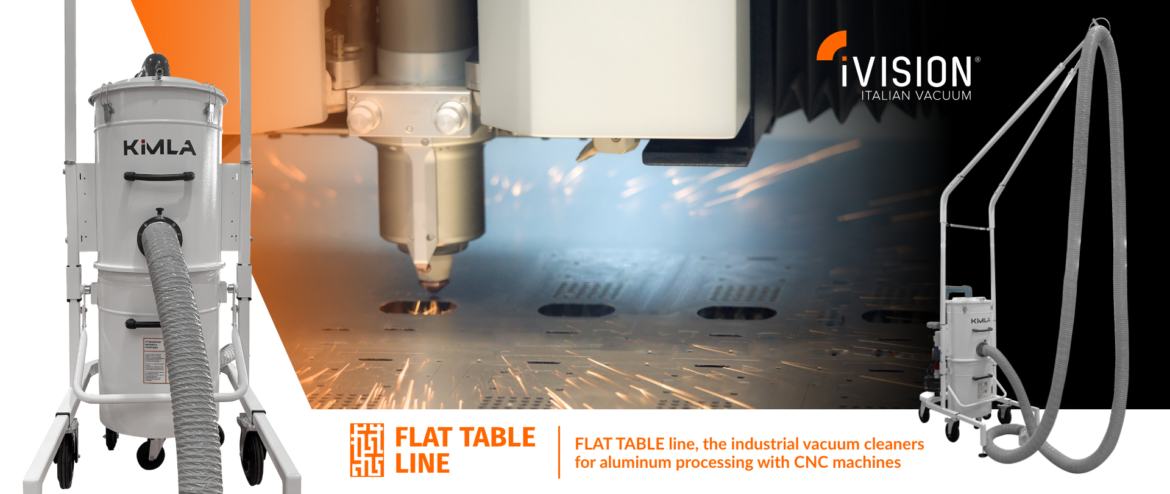

iVision industrial vacuum cleaners were chosen by KIMLA, a Poland-based company specializing in the production of CNC machines and fiber laser cutters, which is also engaged in processing, such as cutting and milling, aluminum.

In this case, the vacuum cleaners selected by KIMLA are from the FLAT TABLE line, used for proper suction of aluminum shavings. These vacuum cleaners were installed on CNC machines that process aluminum sheets, later used by a major Dutch company to build luxury yachts.

The process of working with aluminum

The aluminum processing is a multifaceted process that goes through several stages, including:

- MATERIAL SELECTION

Initially, you have to proceed with material selection, choosing the most suitable types of aluminum -with variations in alloy and thickness- for the specific applications required.

- CNC TECHNOLOGY

Next, the material goes through cutting and milling operations, using precision machinery with CNC technology. During this stage, it is important to maintain high standards of precision to ensure the best result.

Effective extraction of aluminum residue is essential to preserve maximum precision during the machining process.

This takes on even greater importance for our client KIMLA, considering that the material is intended for the construction of luxury yachts, where every detail counts to achieve finished products of extraordinary quality and prestige.

- BENDING, DRILLING OR OTHER OPERATIONS

These operations are performed to give the product the desired shape.

- APPLICATIONS OF SURFACE FINISHES

Finally, it is often necessary to apply surface finishes, such as painting or anodizing, to improve the corrosion resistance and aesthetic appearance of the finished product.

Given the complexity of this process, the company relied on iVision Vacuum to handle the collection and vacuum of aluminum residue generated by the CNC machines that process aluminum. This step is critical to ensure product quality, but also to improve operator well-being by creating a clean and safe work environment.

KIMLA company’s suction needs

The company in question, engaged in aluminum processing, has special needs when it comes to vacuuming using CNC machines. In the processing stage, aluminum waste can create problems, both for the cleanliness of the work environment and the health of workers. To address these challenges, it is critical to use specialized vacuum solutions designed to efficiently collect aluminum chips generated while using a CNC machine.

The vacuum cleaners in iVision Vacuum’s FLAT TABLE line, which are equipped with an overhead arm to connect the hose directly to the electro spindle performing the machining, help prevent the suction hose from obstructing the work of the machine.

The vacuum cleaners in this line are designed to keep the work area clean and safe, preventing the accumulation of metal debris and thus helping to preserve product quality and ensure a healthy working environment.

FLAT TABLE line features

The FLAT TABLE line is the result of direct expertise in the field of industrial mechanics, where a powerful, reliable suction system is needed to safely remove chips generated during the machining process.

FLAT TABLE vacuum cleaners, with a side channel blower, are ideal for 3-axis, horizontal or vertical CNC machines that require accurate and efficient suction of the waste produced to ensure maximum precision during the machining process and a final product free of imperfections. In addition, they can be equipped with patented industry-specific accessories. These include, for example, the functional overhead arm, supplied to KIMLA to meet its industrial suction needs when operating the CNC machine on aluminum sheets.