The term HEPA (High Efficiency Particulate Air) denotes a high-efficiency filtration system, which is used for microparticles, fine dust and oil mists. This category of filter assumes a key role within vacuum cleaners, as it allows them to capture contaminants before they can affect machine’s head. In this way, it is possible to ensure high vacuum cleaner efficiency and, at the same time, safeguard operators’health by putting filtered and purified air back into the environment.

Classification of dusts and filters

Before listing the technical features and functionality of the HEPA filter, we want to examine how dust and filtration classes are divided.

Classification of dusts

We can classify dusts according to the risk they may cause to operators and according to its granulometric size.

- Class L

This class includes dusts representing a moderate risk for operators’health and distinguish by a particle size of less than 3 microns.

- Class M

Class M includes dusts that represent a medium risk for operators’health, their particle size is less than 2 microns.

- Class H

Dusts classified within Class H are dusts that are very harmful for operators’health, falling into the category of high-risk dusts. Their particle size is less than 1 micron and they also include carcinogenic dusts.

Classification of filters

There is a classification for filters too, it is made according to their filtering capacity.

- L-type filter

Vacuum cleaners with an L-type filter are able to vacuum up to 99% of dust with a size of 3 microns. These filters are usually used for vacuum cleaners employed for general cleaning, where they come into contact with dust that doesn’t cause a high risk to operator’s health.

- M-type filter

M-type filter captures 99% of dust that is up to 1 micron in size. In this case, it is mounted on vacuum cleaners used in different industries that require high filtration efficiency.

- H-type filter

In this classification we find filters that can offer the highest suction and filtration capabilities. These filters capture up to 99.995% of dusts that has a size as small as 0.18 microns.

What is HEPA filter

HEPA filter is also known as “absolute filter” because of its high filtration efficiency and is essential for all areas where harmful dusts is produced. This filter falls under the classification of H–type filters due to its 99.995% filtering capacity of 0.18 micron dust.

The composition of a HEPA filter

HEPA filter consists of microfiber filter sheets assembled in several layers and separated by aluminum septa. The filter sheets block pollutant particles that are present in the area to be treated. Because of their versatility, HEPA filters can be applied upstream, downstream or on other locations in the filter path of an aspirator, or can even be mounted in series.

The types of HEPA filter and its functionality

In accordance with the UNI EN 1822 standards, HEPA absolute filters are characterized by high filtration efficiency and can be classified into 5 classes (from H10 to H14) based on their 0.3 micron particle filtration capacities:

- H10: retains up to 85% of particles

- H11: retains up to 95% of particles

- H12: retains up to 99,5% of particles

- H13: retains up to 99,95% of particles

- H14: retains up to 99,995% of particles

The particles that the HEPA filter is able to trap are particles that are invisible to the human eye, just think that the size of a grain of sand has a diameter of 90 microns. The smaller these particles are, the more dangerous they are to the health of the operators because they are able to enter deep into the lungs, eventually entering the bloodstream.

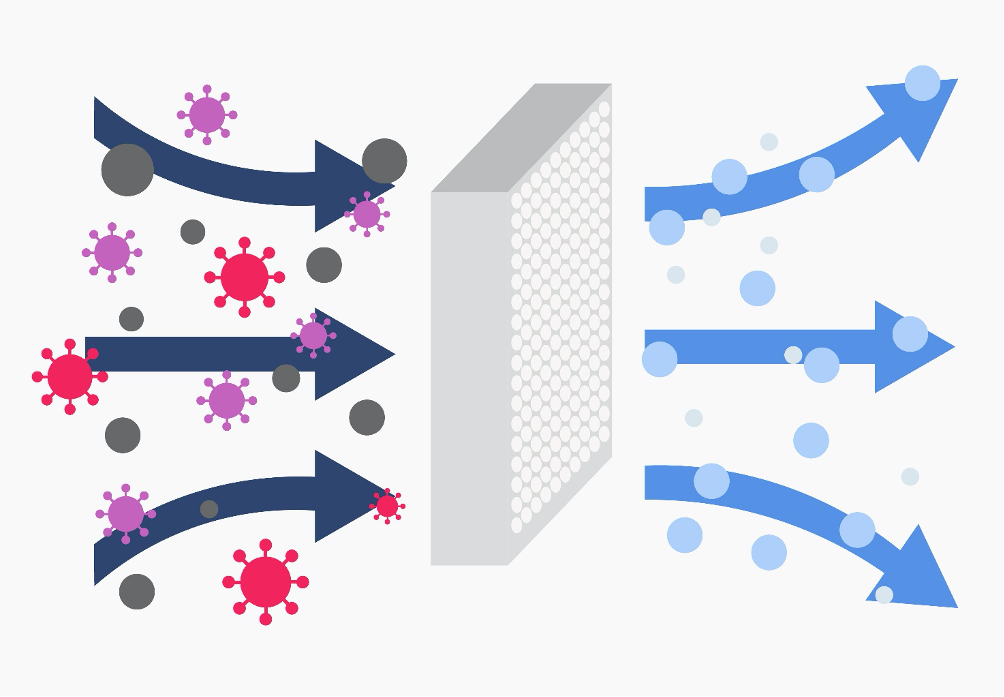

In terms of operation, the HEPA filter blocks particles in 3 different ways:

- Impact

Large particles, once they come into contact with the filter, can not cross the filter structure, in this way they remain trapped outside.

- Interception

Airborne particles become trapped within the intricate fiber structure.

- Diffusion

Diffusion is the mode that succeeds in trapping smaller particles, these collide with each other until they change direction and quickly lose speed.

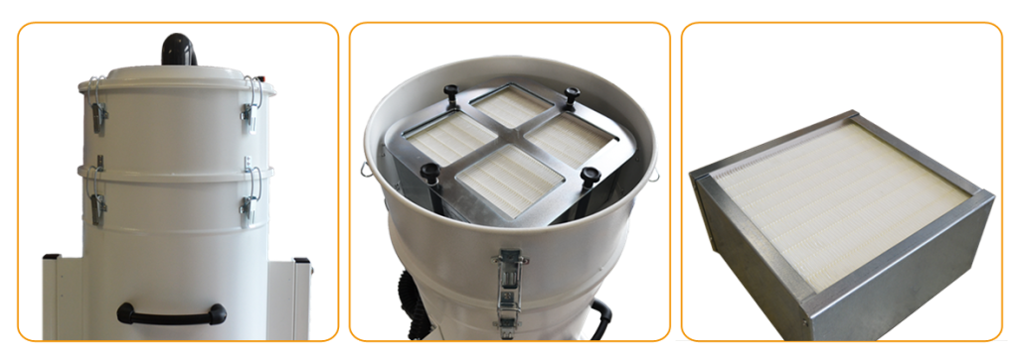

HEPA filtration in industrial vacuum cleaners

HEPA filtration fitted in industrial vacuum cleaners is essential for all those companies working in industries where fine and harmful dust is generated. In fact, this filter is the most suitable tool for:

- Retaining pollutant particles that could be dispersed into the air;

- Slow down the wear and tear of the vacuum cleaner, as it prevents micro-dust from coming into contact with the engine head, risking to affect its efficiency.

In addition, some industries are required by law to use industrial vacuums with absolute HEPA filters, since they must comply with strict air quality requirements.

The sectors concerned are:

- Food

- Chemical

- Cosmetic

- Electronic

- Pharmaceutical

- Mechanical

- Steel

- Textile

In all these areas, it is extremely important that the filtered air is completely free of any residual pollutants, viruses or bacteria potentially toxic to workers or the success of the final product. Thanks to the HEPA filter, it will be possible to avoid both pollution of the external environment and toxic contamination of the internal air breathed by workers.

Contact us to find out more about the most suitable filter for your industrial vacuum cleaner!